Measure quality objectively

Collect in-line quality measurements with the industry’s most scalable computer vision software, compatible with any industrial camera. Ethon detects and counts defects, connects them to process data, and reveals the factors that drive product quality.

Deliver fast and consistent defect detection. Integrate with any industrial camera and learn from just a few defect-free images.

The first visual inspection workflow powered by a vision foundation model built specifically for manufacturing.

Requires fewer than 25 defect-free images to set up, enabling deployment in under 10 minutes without days of data labeling or model tuning.

Benchmarks show Ethon’s vision foundation model consistently outperforms other quality inspection approaches across diverse product types.

Achieved through reduced false rejects, fewer undetected defects, and the consolidation of fragmented legacy inspection systems into a single platform.

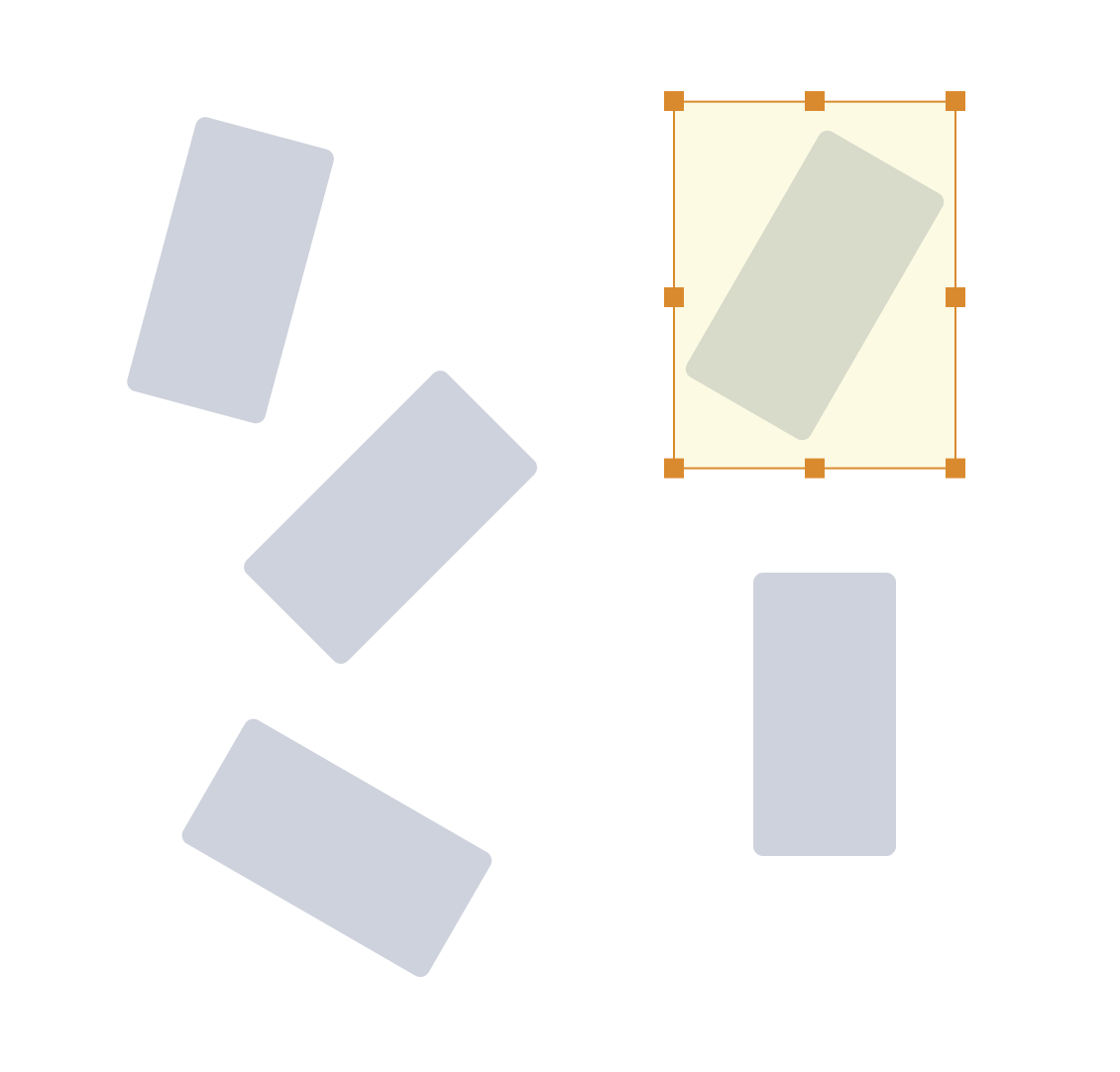

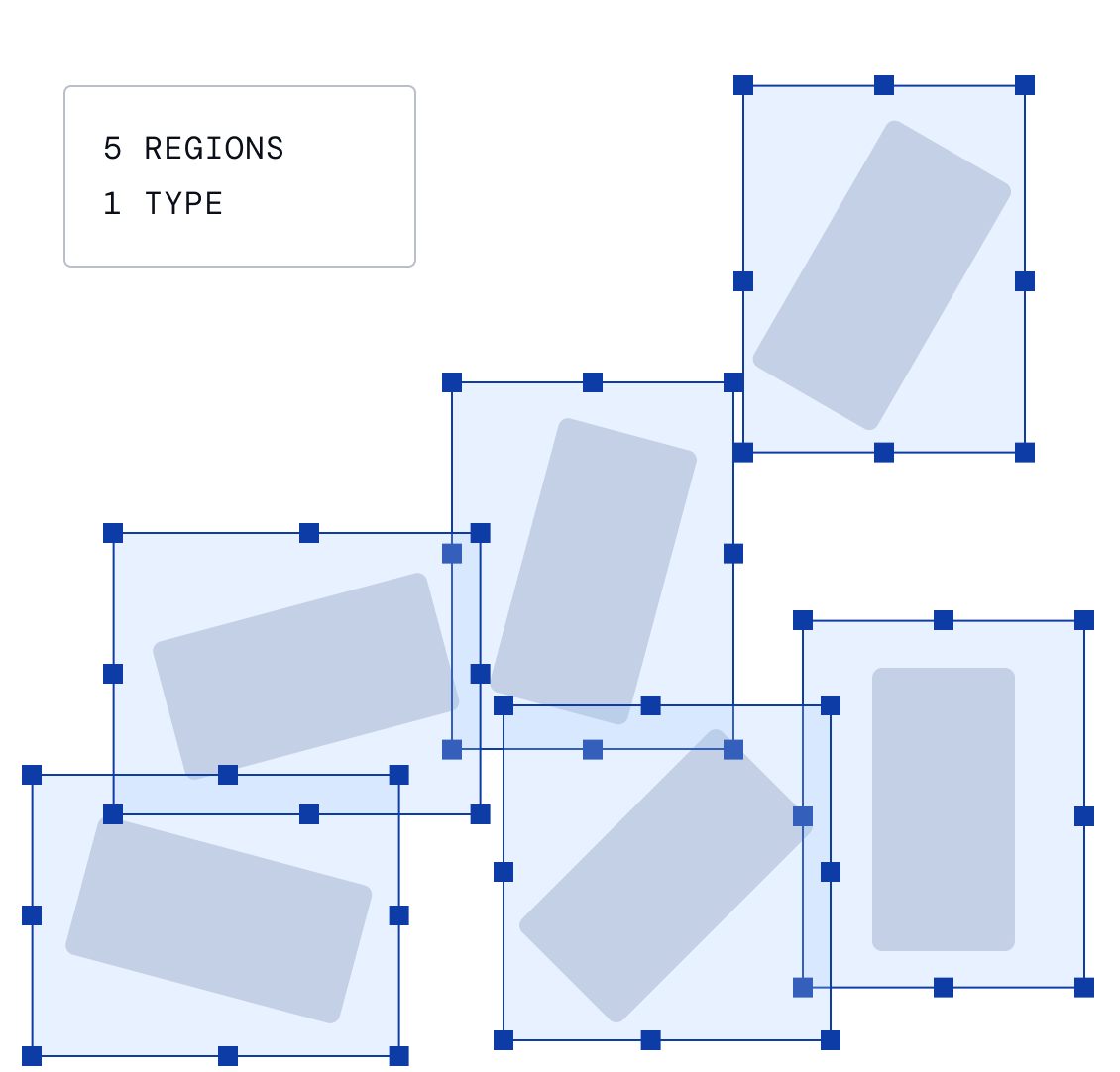

Annotate objects with visual prompts

Using one visual prompt, the foundation model automatically finds and annotates matching regions across images. These annotated images then serve as the basis for training a model that is ready for production.

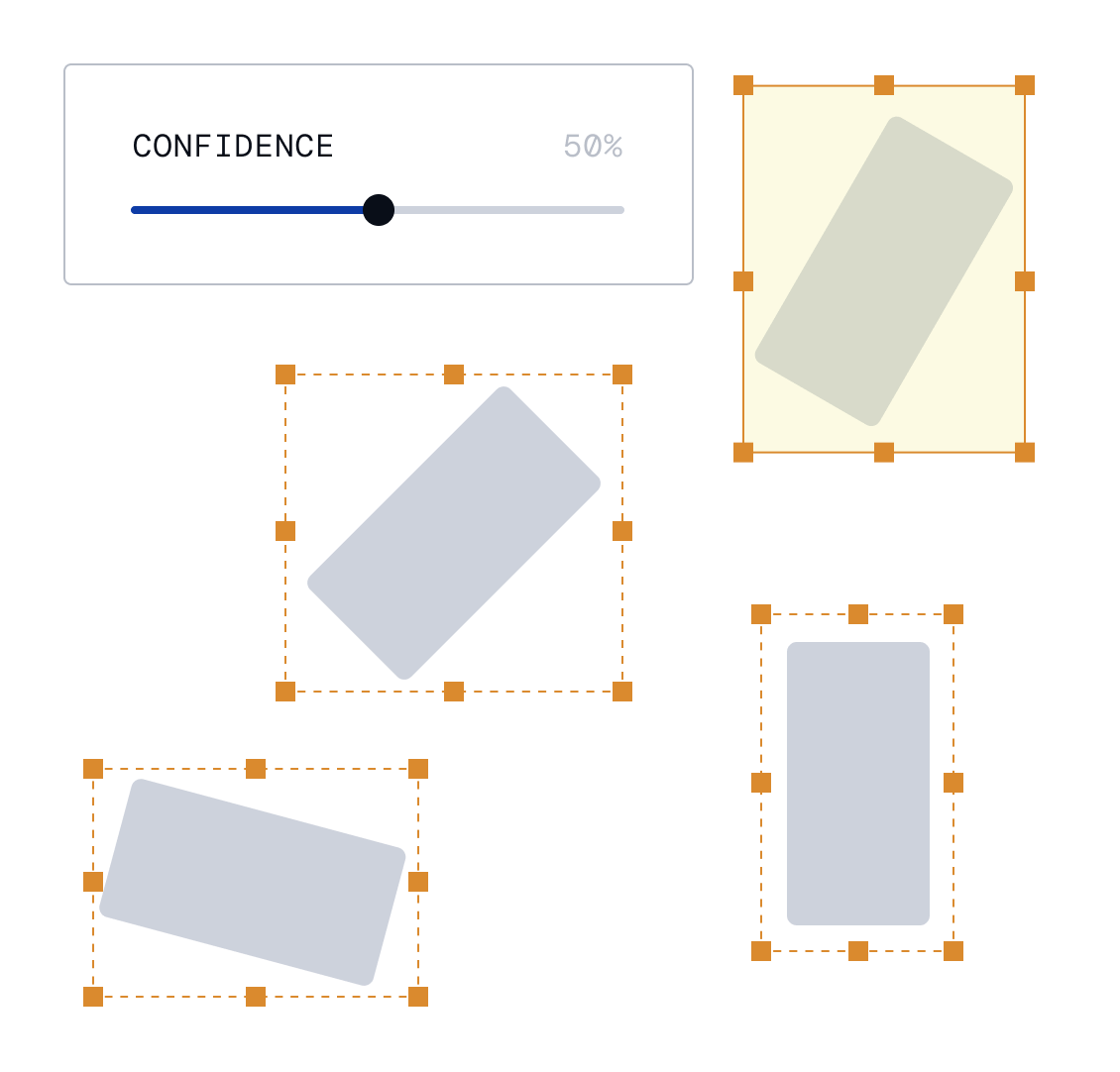

Set inspection sensitivity

Users define how strictly the model should treat visual deviations as defects. This sensitivity setting determines how the system learns what “normal” looks like and how strongly deviations are flagged during live inspections.

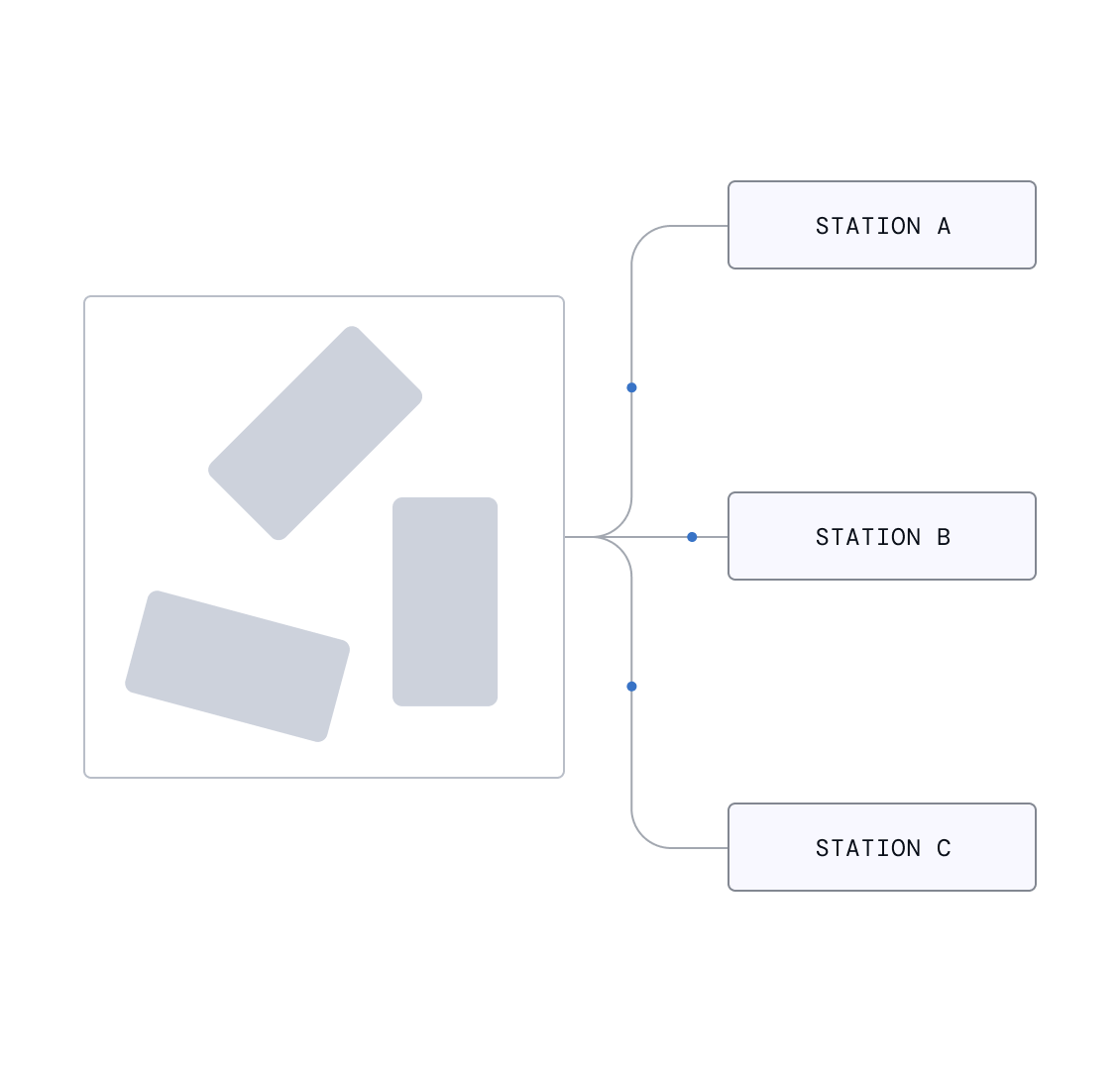

Deploy inspections jobs to stations

Once annotation and thresholding are complete, the inspection job is deployed to one or multiple inspection stations. The workflow is hardware-agnostic, allowing seamless integration with any existing camera system on the line.

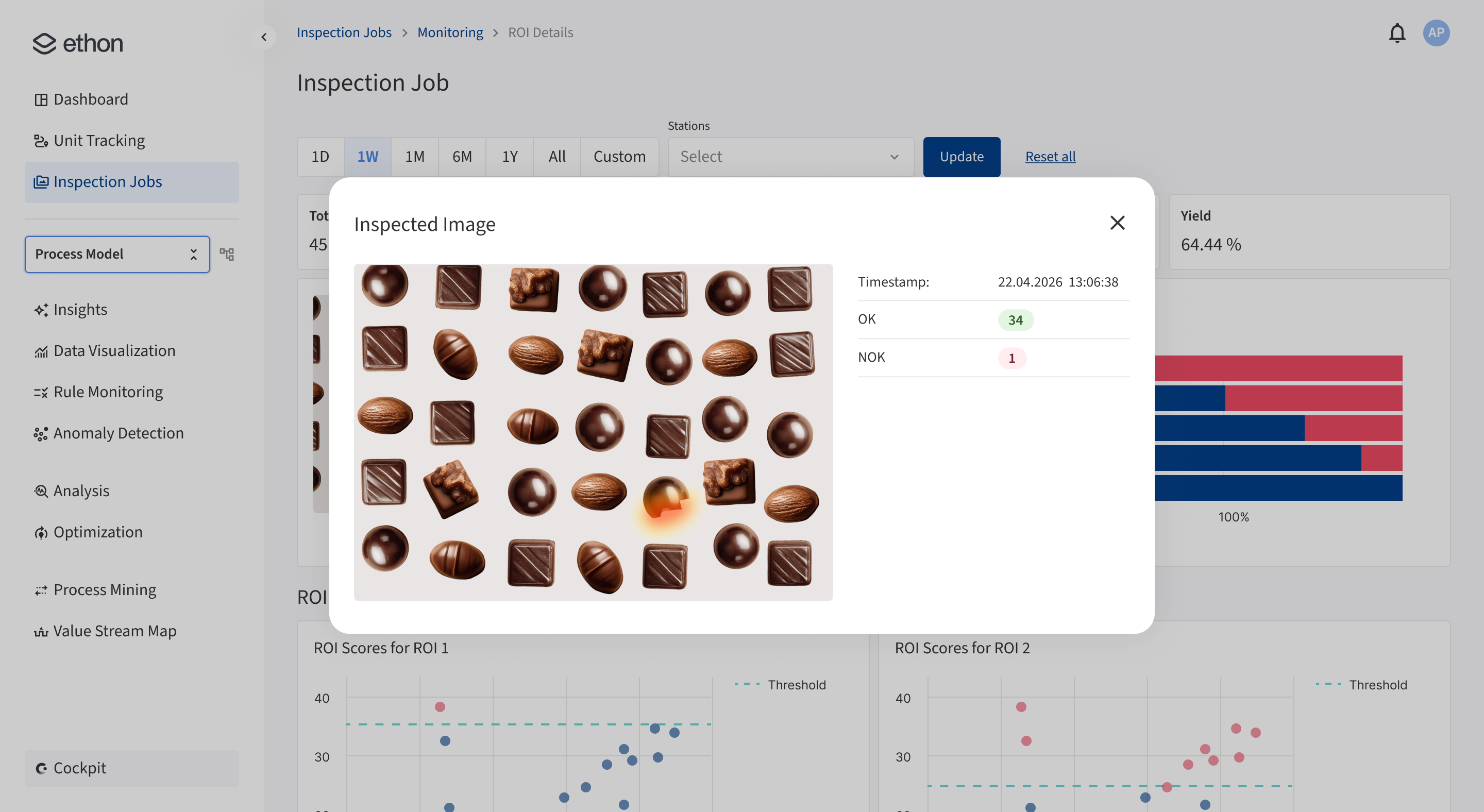

Detect objects in real-time

Ethon monitors production lines in real-time and detects products in varying positions and orientations. Each product is evaluated against the learned normal appearance, enabling reliable inspection even when positioning varies.

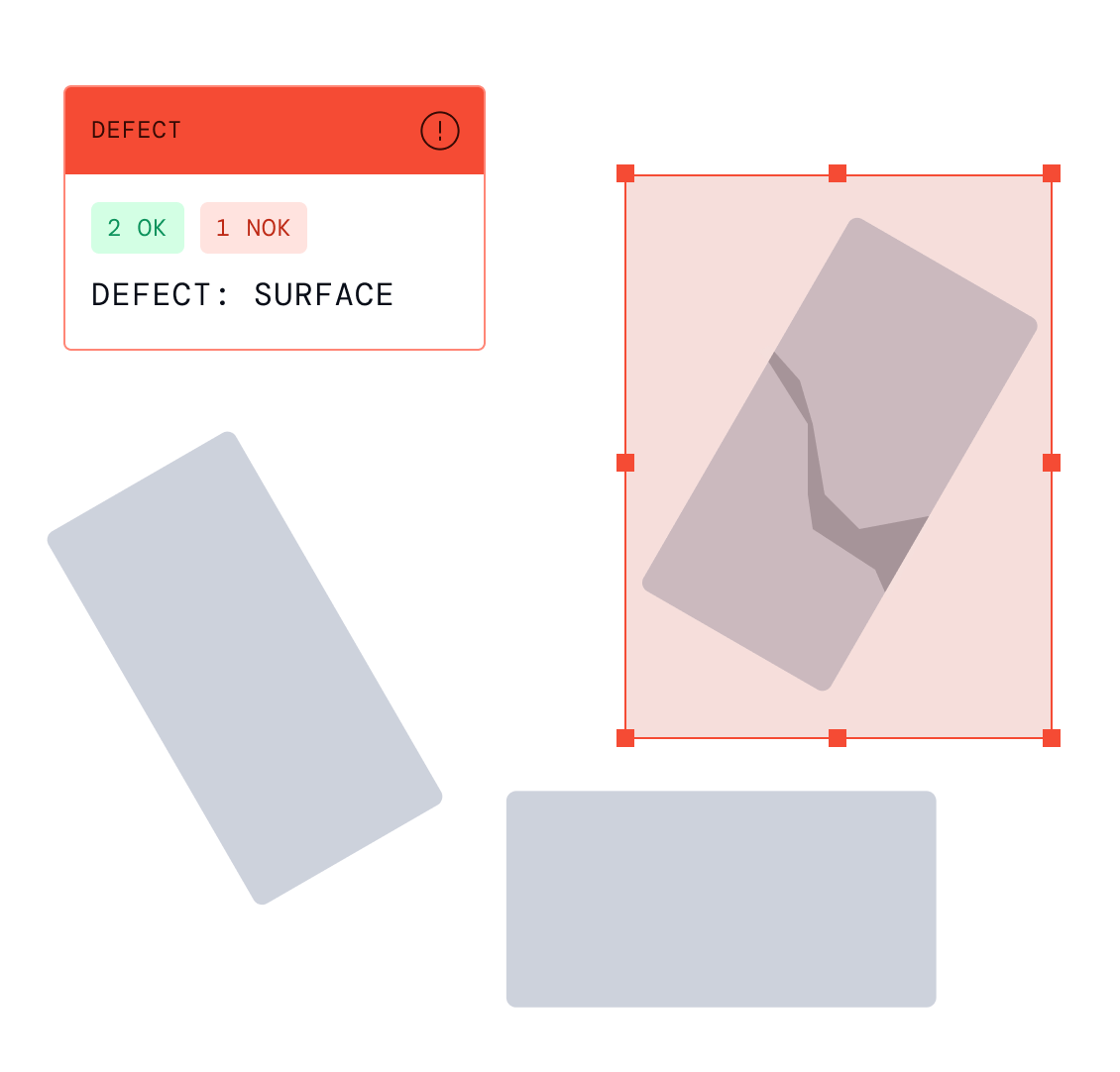

Trigger actions on defects

When a defect is found, the software flags it immediately. Defects can be counted for quality KPIs, reviewed by operators, or used to trigger automated actions — such as rejecting a faulty product on a fully automated line.

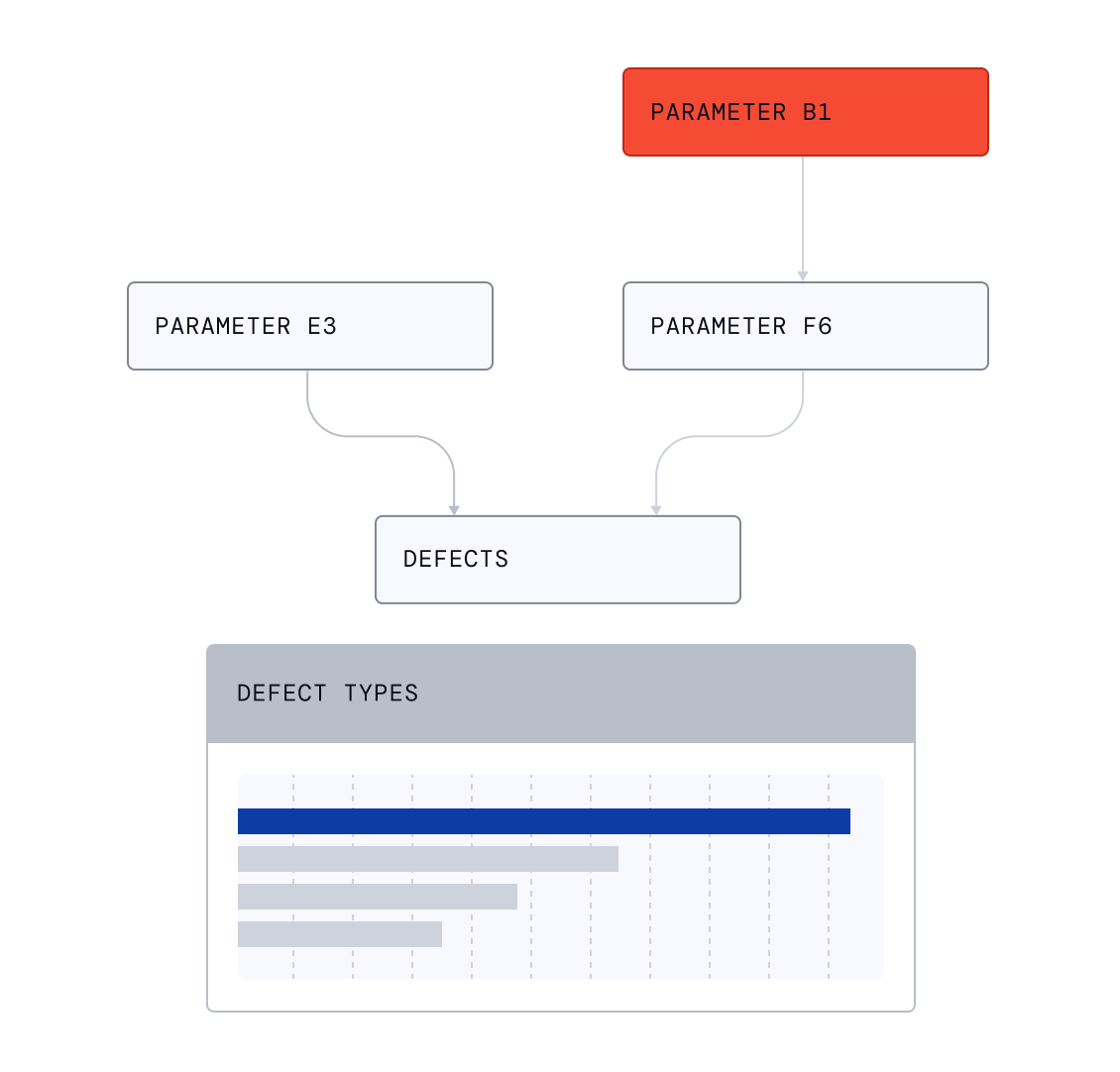

Feed quality data into improvement workflows

Ethon captures all relevant context at the source: part numbers, region types, station information, defect counts, and other production metadata. These enriched inspection results flow directly into the wider Ethon platform, where they can be combined with workflows such as Process Optimization or Root Cause Analysis, closing the loop between detection, diagnosis, and prevention.