Keep production stable as conditions change

Close the loop on process control. Ethon monitors every critical parameter in real time, automatically adjusts setpoints when processes drift, and keeps lines running at peak performance.

Keep processes stable and centered. Identify drivers of drifts and adjust controllable parameters accordingly.

The first process control workflow that combines advanced Causal AI technology with automated setpoint steering.

Benchmarks show Ethon’s causal models consistently find the setpoints that most effectively reduce drift and stabilize the process.

Customers have achieved significantly tighter process control through live causal steering that continuously corrects deviations.

Proven across active deployments through reduced variability, fewer manual adjustments, and more consistent in-spec production.

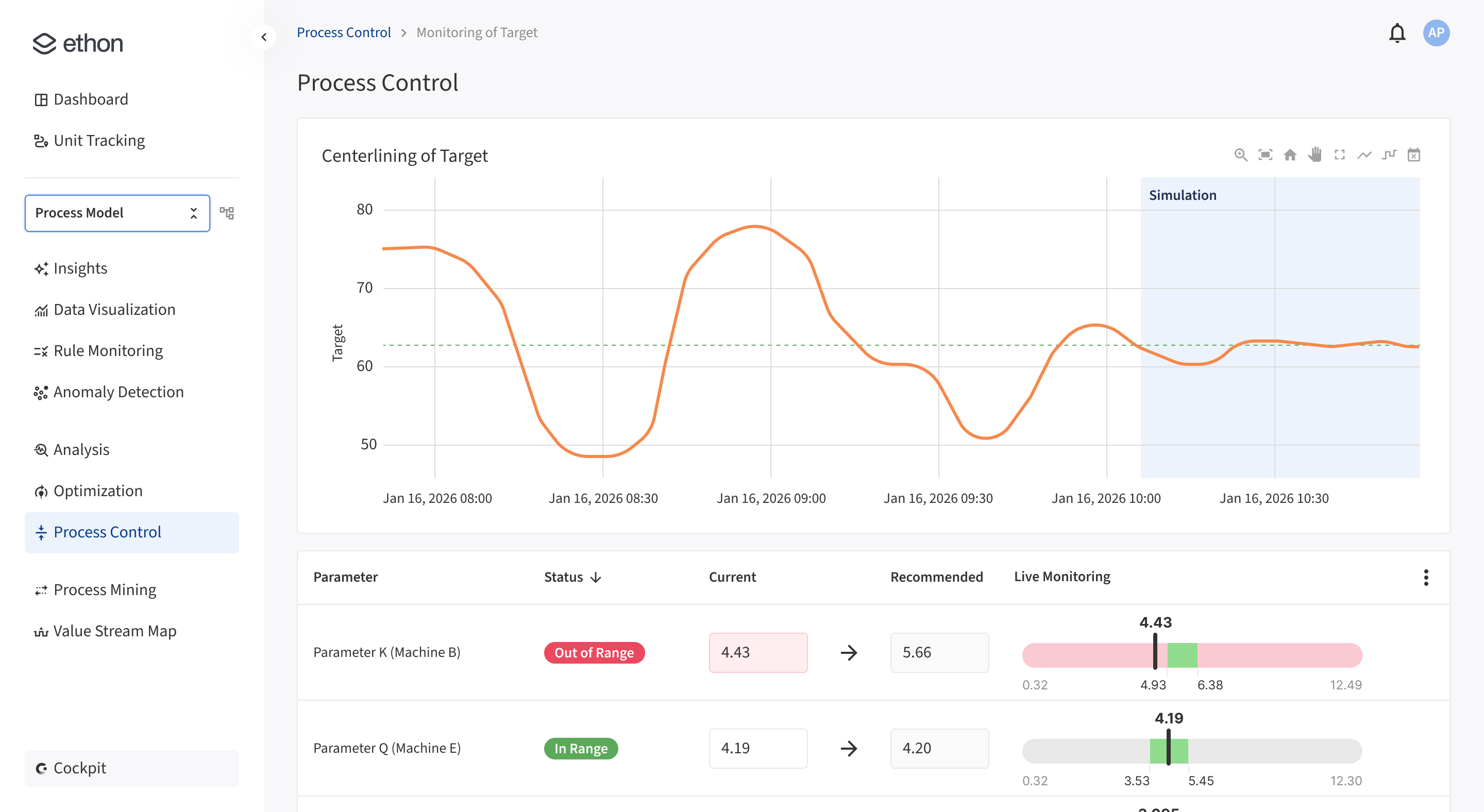

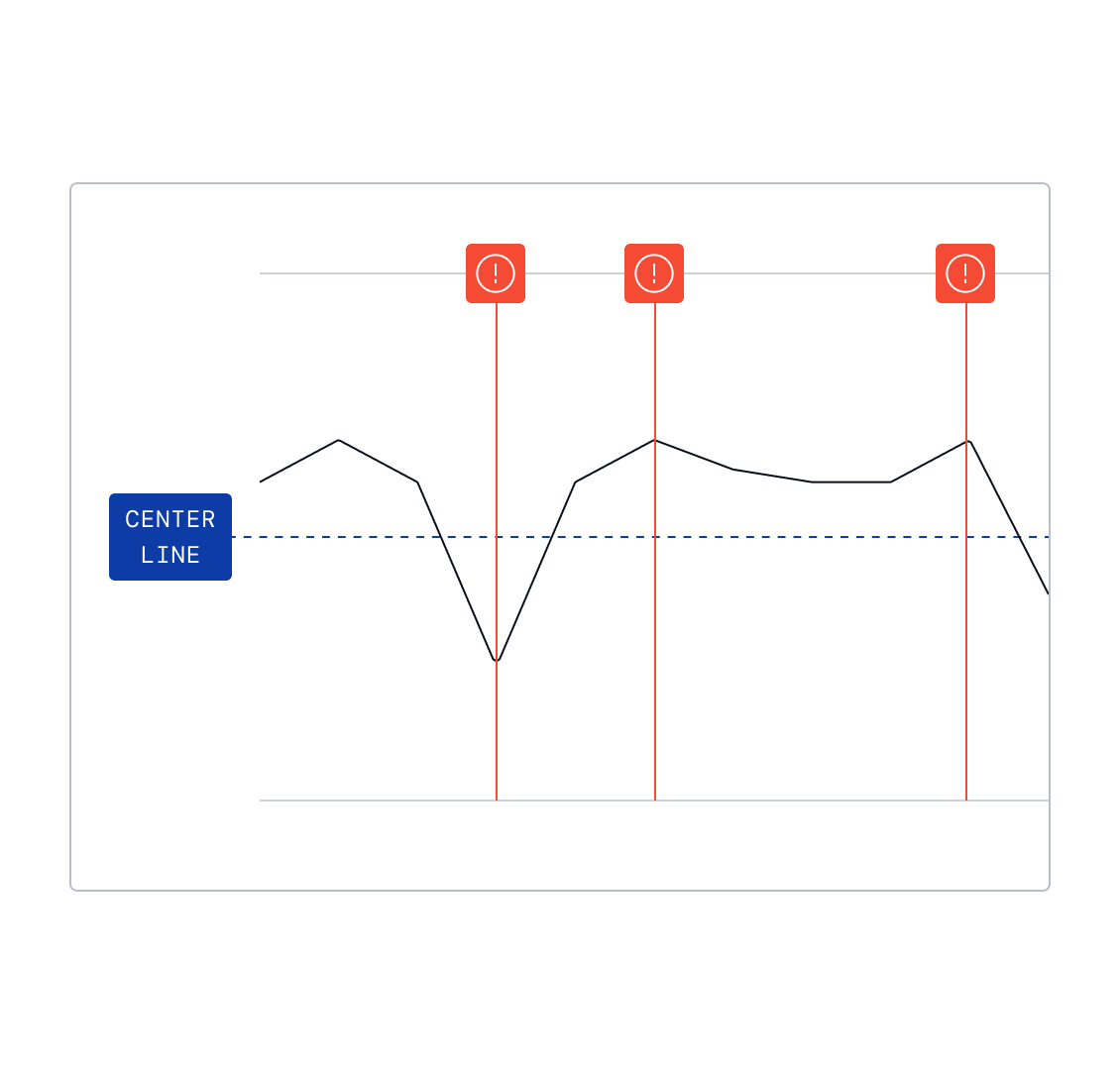

Detect process drift in real-time

Ethon continuously monitors critical process parameters against defined targets. When a value starts to move off-center, agents detect the deviation immediately and trigger an automated diagnostic workflow.

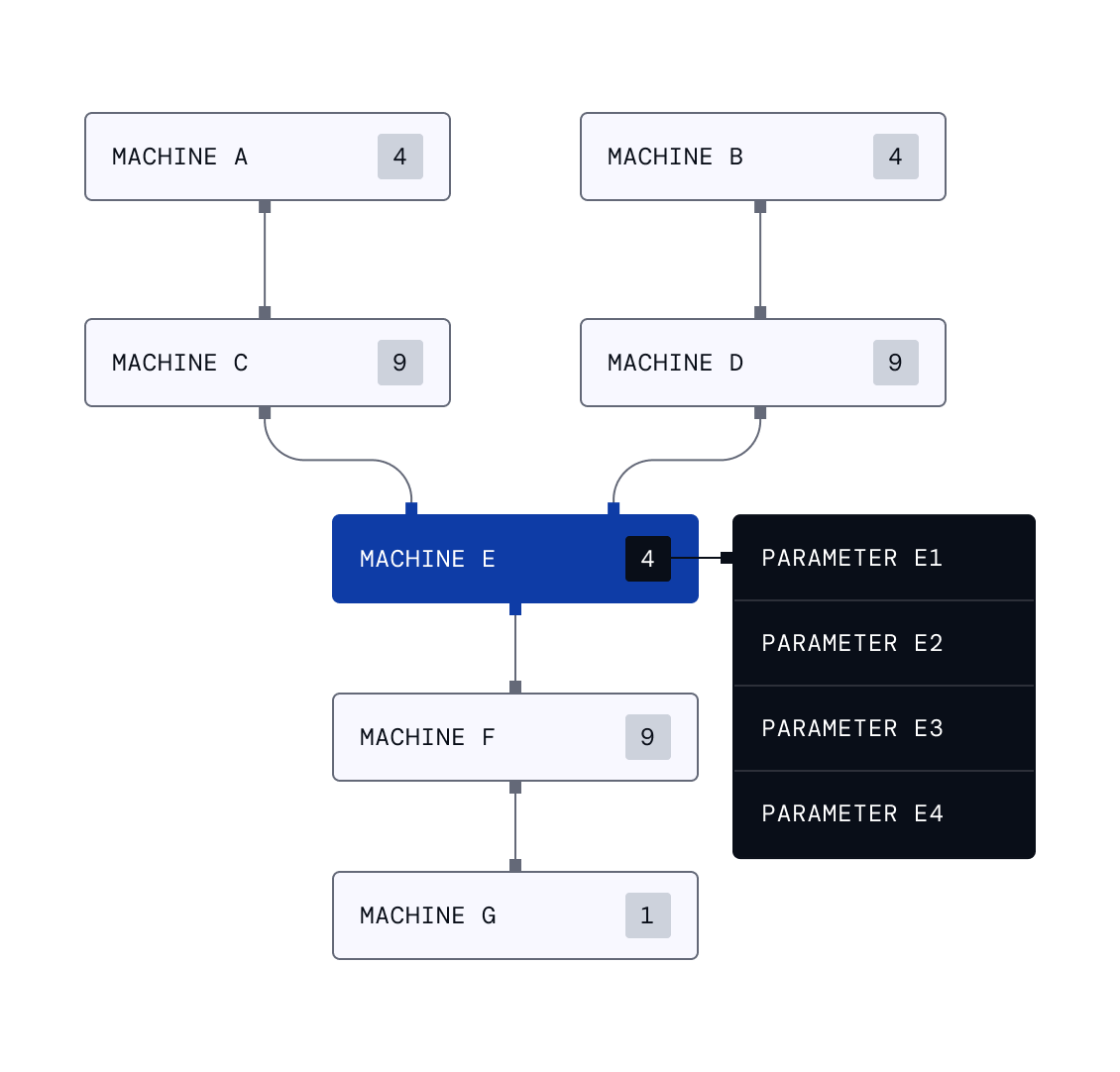

Auto-aggregate all relevant data

Ethon compiles all parameters that influence the drifting outcome, including every controllable setpoint on the line. Data is aligned across equipment and process steps, ensuring the optimization is grounded in a complete, structured representation of production.

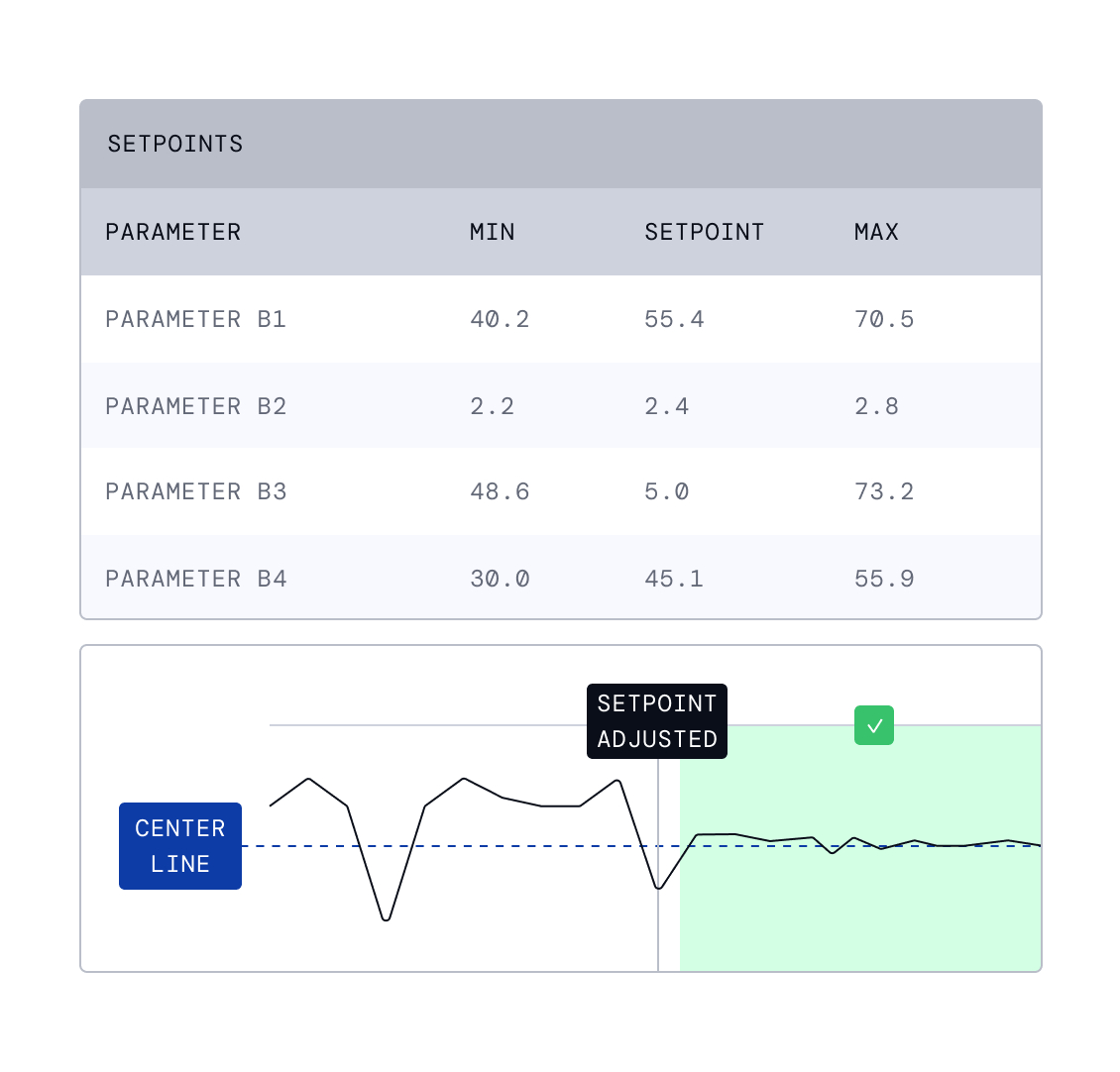

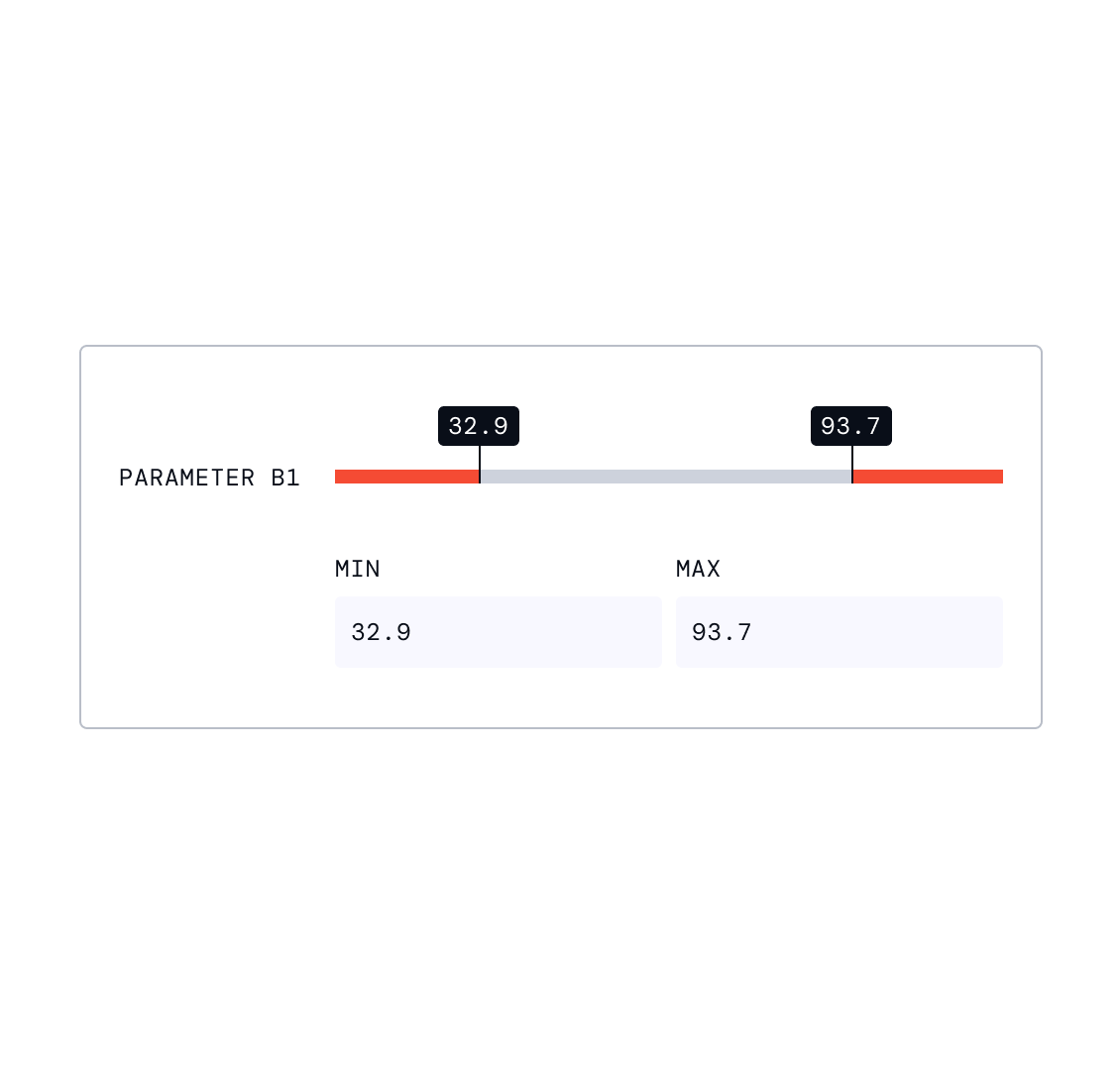

Define safe operating ranges

Engineers define minimum and maximum allowable values for each adjustable setpoint. These ranges ensure that automated steering operates safely, respects equipment constraints, and adheres to process rules.

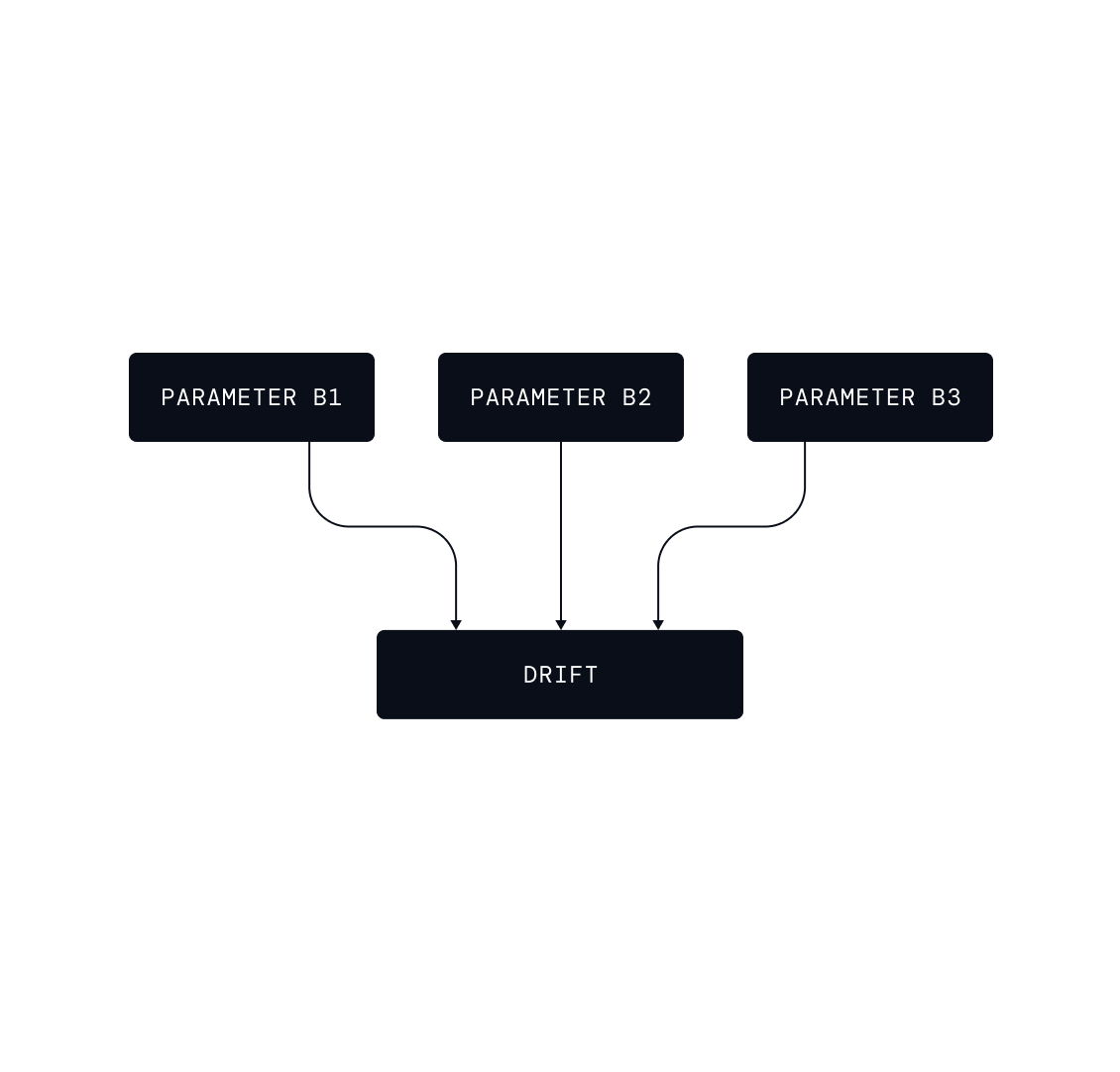

Model how drift propagates

Using the process knowledge graph, Ethon’s causal model understands how process parameters, machine setpoints, and environmental conditions drive the detected drift. The causal model mirrors real process behavior, revealing how changes propagate through the line.

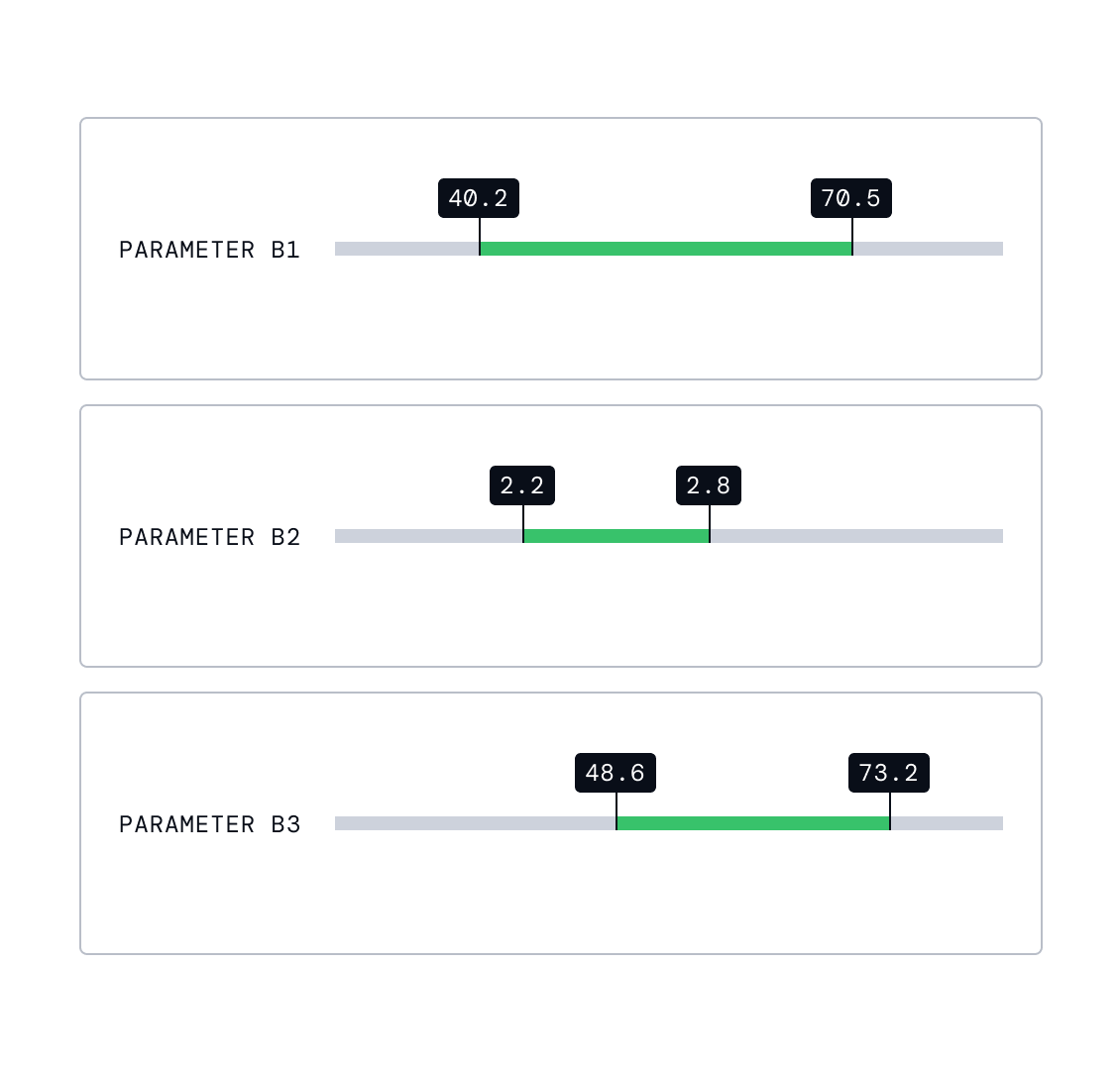

Compute corrective setpoints

Based on the causal graph and historical behavior, Ethon computes the optimal setpoints to counteract the drift. Recommendations include direction of change, magnitude, and expected impact on process stability.

Steer processes continuously

Ethon continuously monitors conditions and updates recommended setpoints as the process evolves. Operators can apply adjustments directly via SCADA HMI, or recommendations can be pushed to PLCs for automated control—keeping the process centered with minimal manual intervention.