Trace every product and batch

Reconstruct the true flow of every part and batch across production. Ethon assigns data to each unit, traces it through every process step, and reveals deviations, rework loops, and bottlenecks from real production behavior.

Make material flow fully transparent. Expose inefficiencies and process deviations across the line.

The first workflow that turns event data into an end-to-end view of material flow.

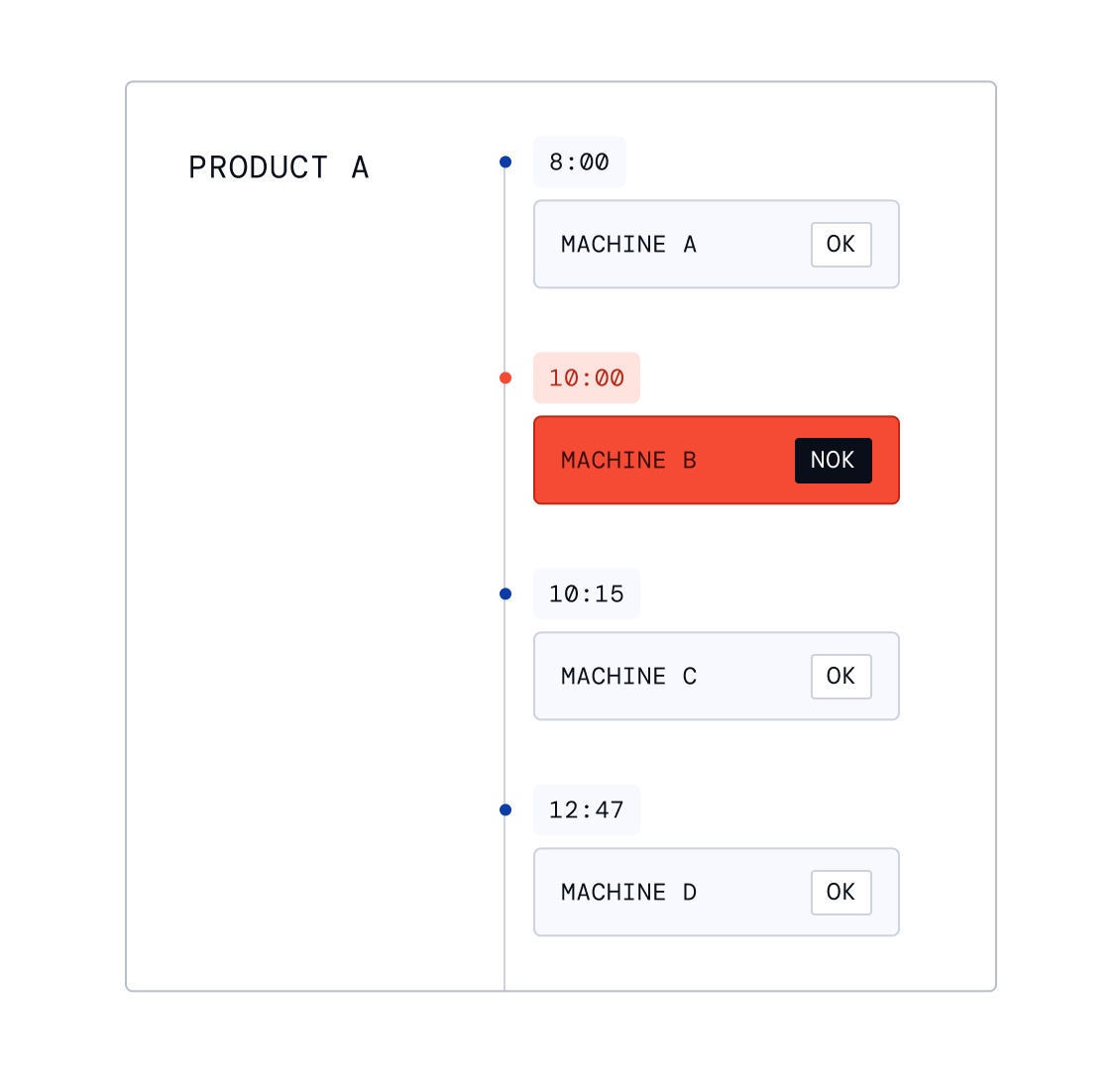

Trace every part or batch

Ethon automatically traces every part or batch through all process steps. Each unit receives a complete, searchable history that shows where it came from, which equipment it passed through, and which conditions it experienced.

Unify production data from all sources

Data from Historians, MES, ERP, vision systems, and sensors are assigned to the correct part or batch. This creates a reliable, system-agnostic tracking system that consolidates all production information in one place.

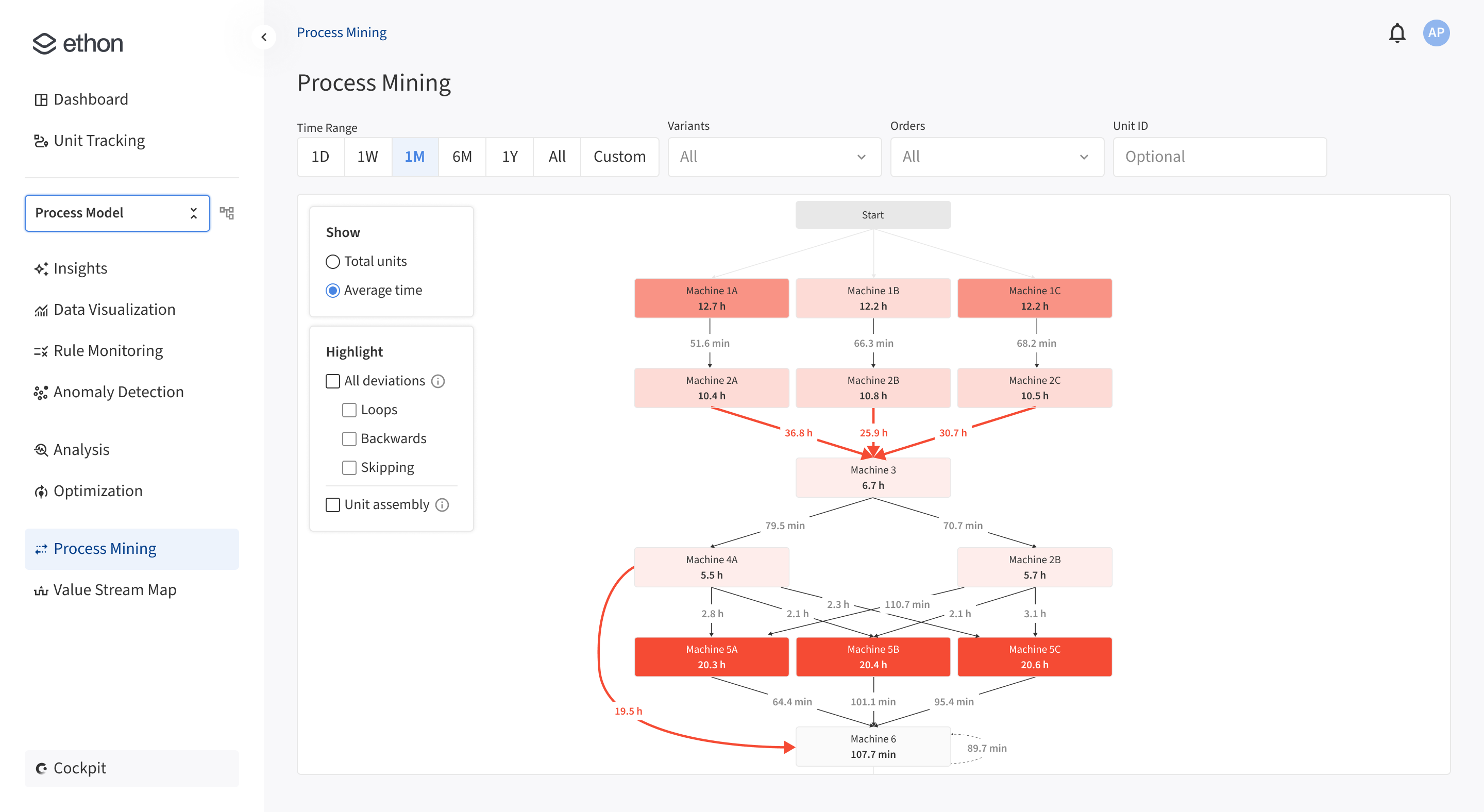

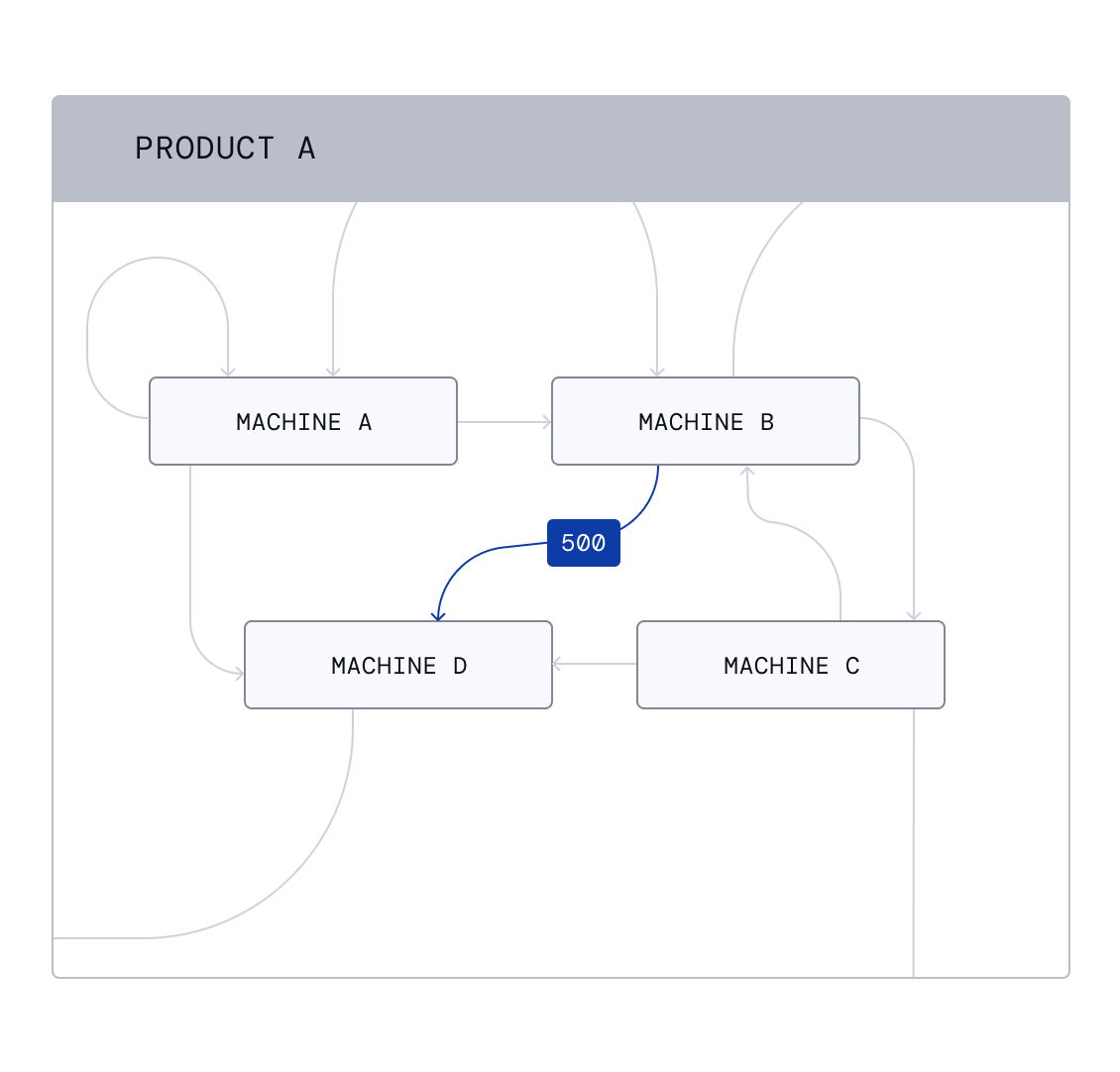

Reconstruct actual process flow

Using process mining algorithms, Ethon reconstructs the actual flow of material through production — not the theoretical flowchart. Every routing choice, transition, branch, and rework loop is captured directly from real event data.

Diagnose flow deviations

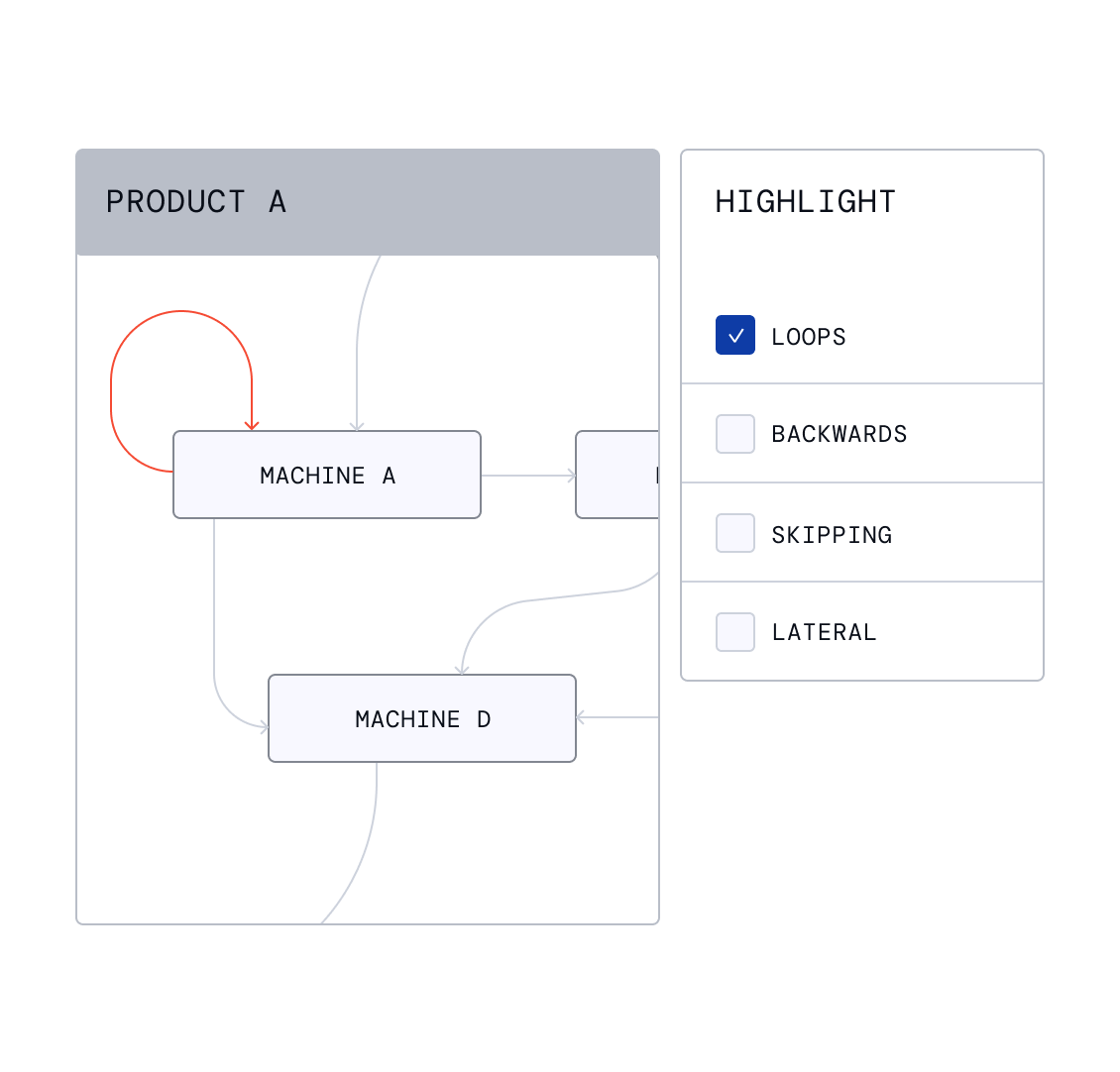

Aggregated across all units, the workflow highlights anomalies such as loops, backward movements, and skipped steps. Engineers can immediately see where the process deviates from the intended flow.

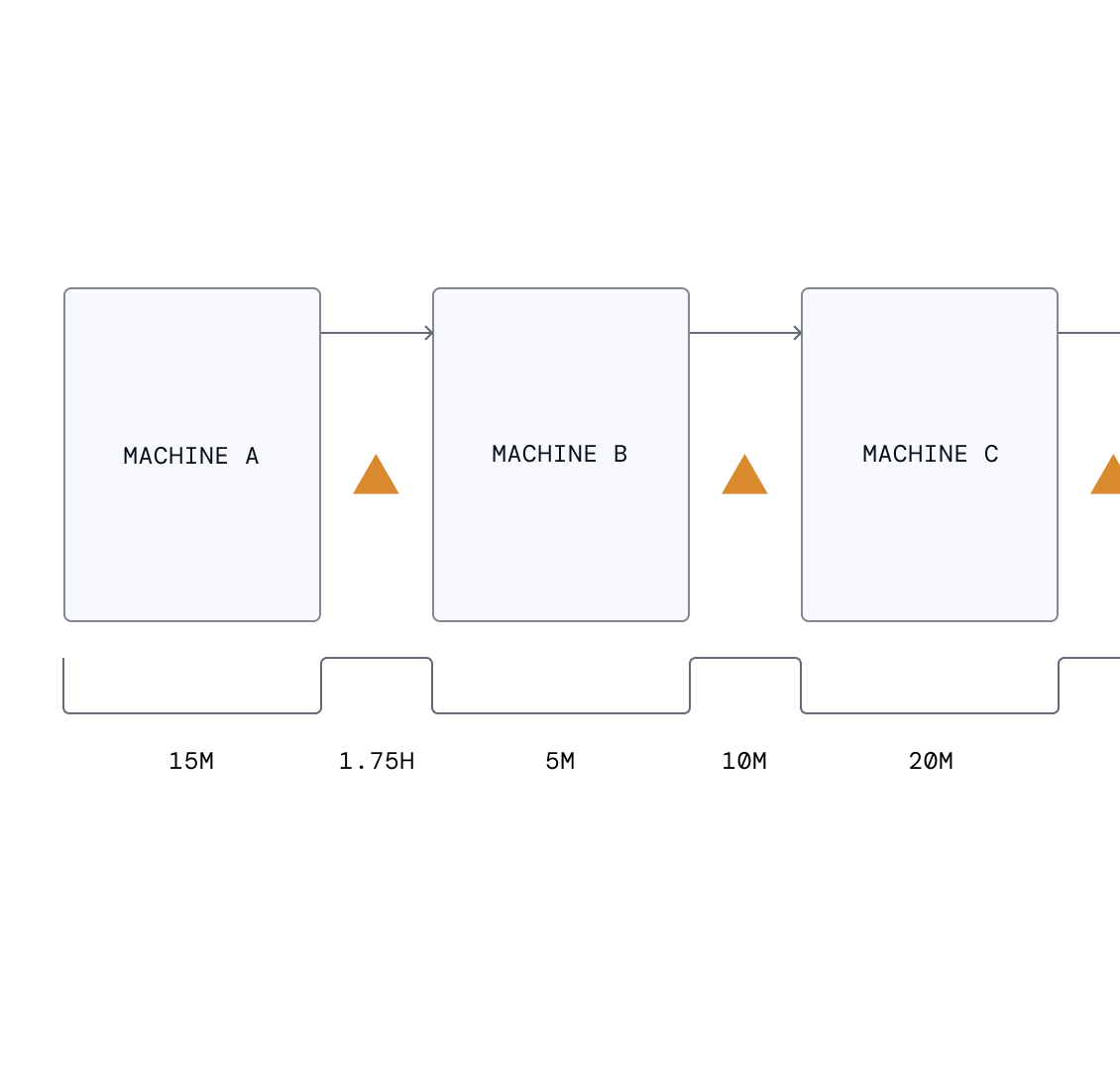

Create digital value stream maps

Ethon creates digital value stream maps from real production behavior. They show throughput, waiting times, inventory, and constraints across the full flow — providing a data-driven foundation for debottlenecking.