Identify and eliminate hidden waste

Deliver step-change productivity across your lines. Ethon continuously scans all process data, spots hidden inefficiencies, and recommends the optimal parameter setpoints to optimize quality and throughput.

Identify hidden inefficiencies and compute optimal setpoints based on cause–effect relationships.

The first process optimization that continuously improves production outcomes with Causal AI technology.

Benchmarks show Ethon’s causal models consistently uncover more influential parameters than conventional process control systems.

Recommended parameter ranges have achieved results like 80% less scrap, tighter centerlining, and significantly measurable progress toward factory targets.

Proven effective in global enterprise roll-outs by improving labor productivity, reducing waste, and stabilizing processes.

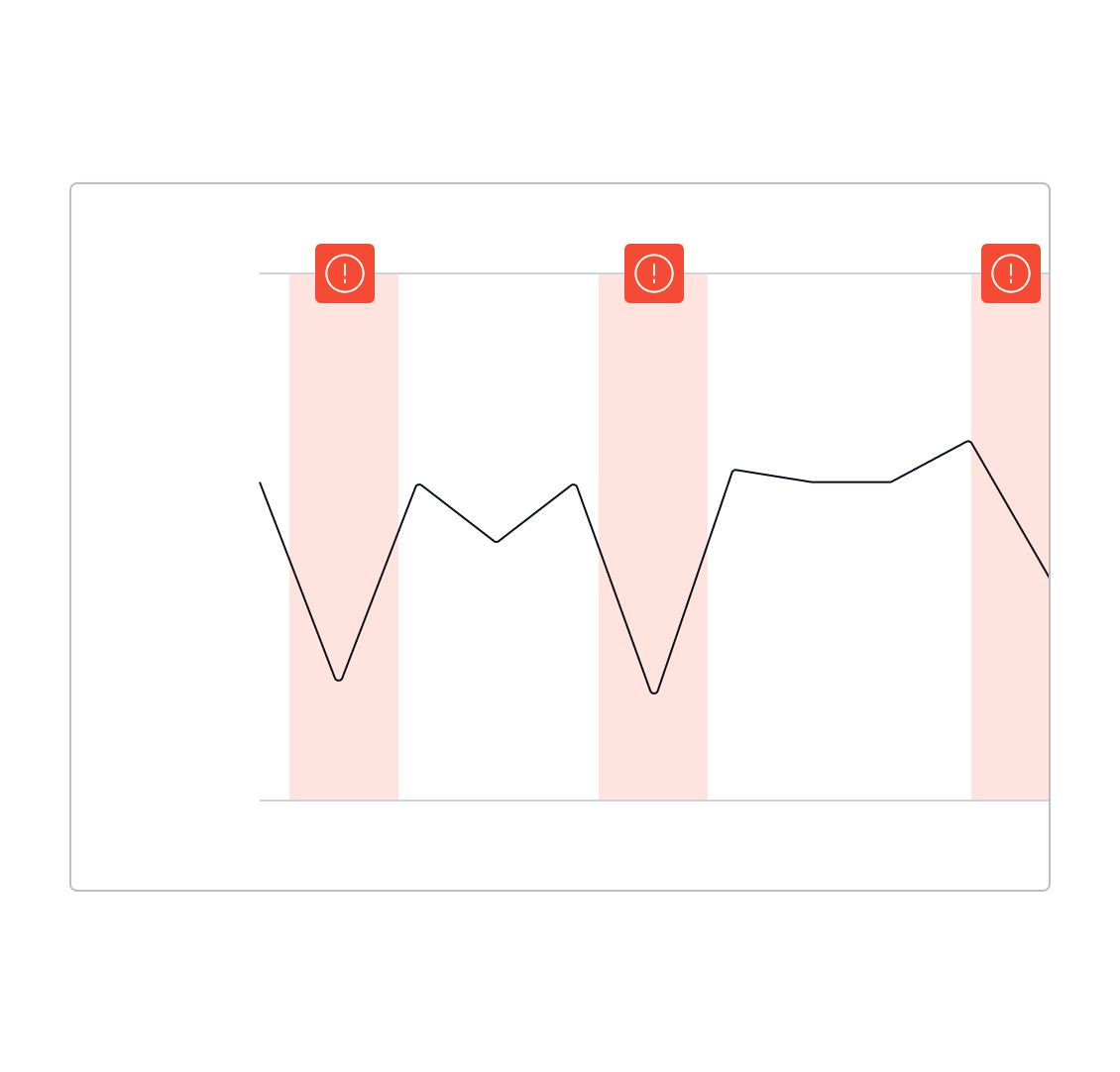

Monitor processes continuously

Ethon continuously monitors process parameters, machine setpoints, and operational outcomes (yield, reject rates, etc.). Autonomous agents detect drifts, inefficiencies, and emerging patterns that signal optimization potential.

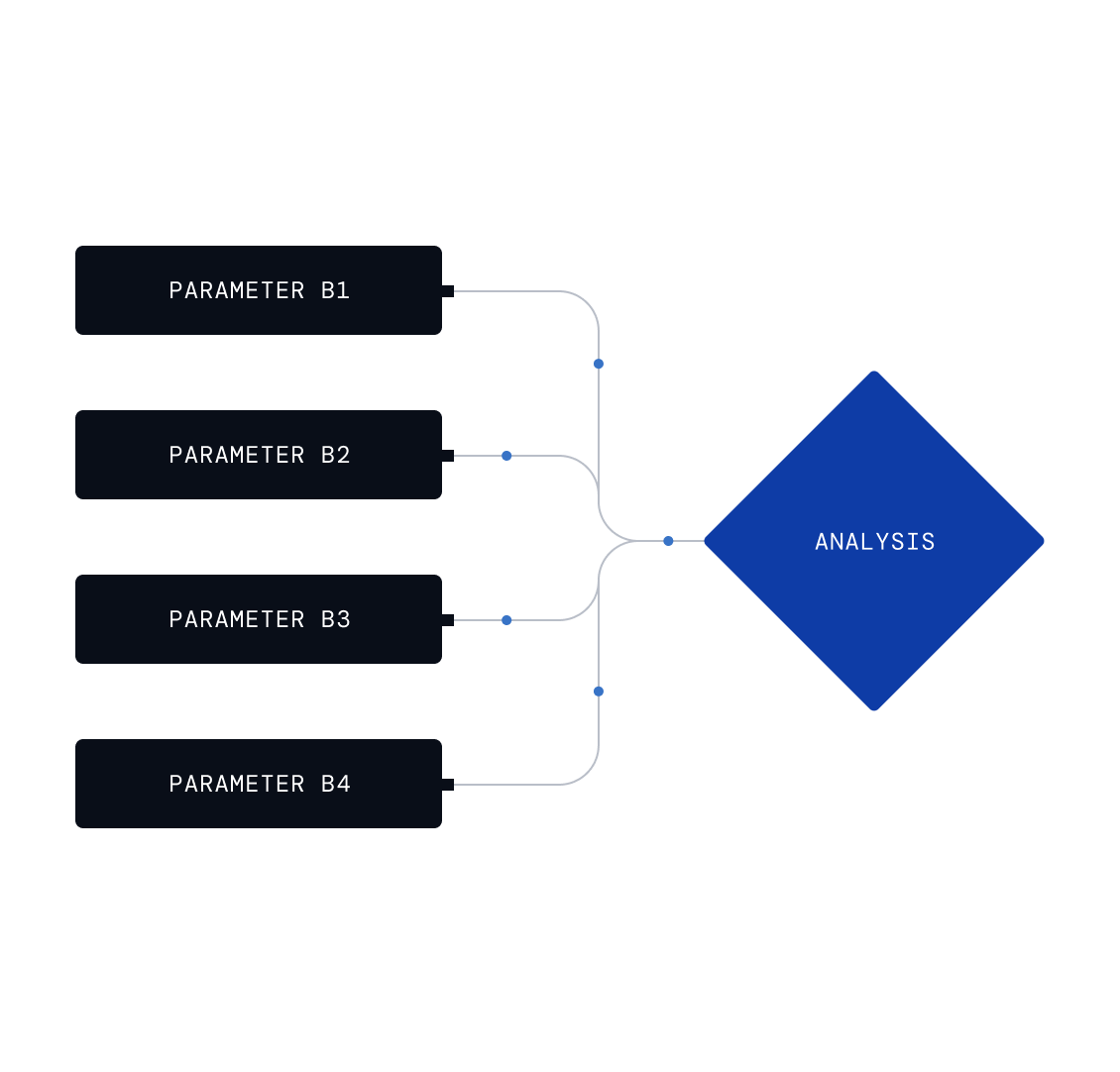

Auto-aggregate all relevant data

Ethon automatically compiles every parameter that could influence the target outcome. It aligns data across units, equipment, and process steps to ensure a complete, structured view of the line.

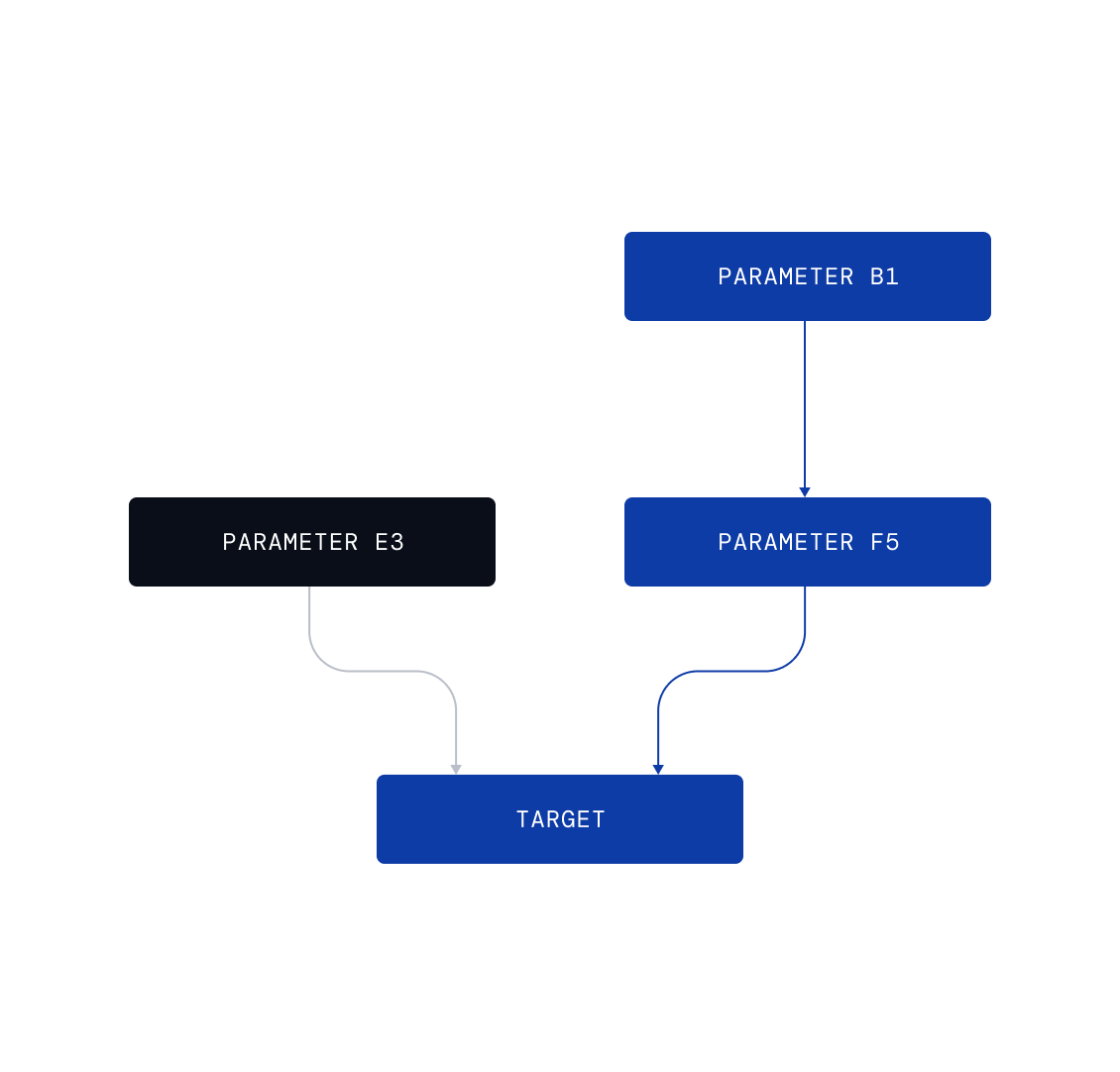

Model how processes actually behave

Ethon uses the process knowledge graph to interpret how each parameter relates to the next. This structure mirrors the physical process, enabling to build a causal model that reflects true cause–effect behavior.

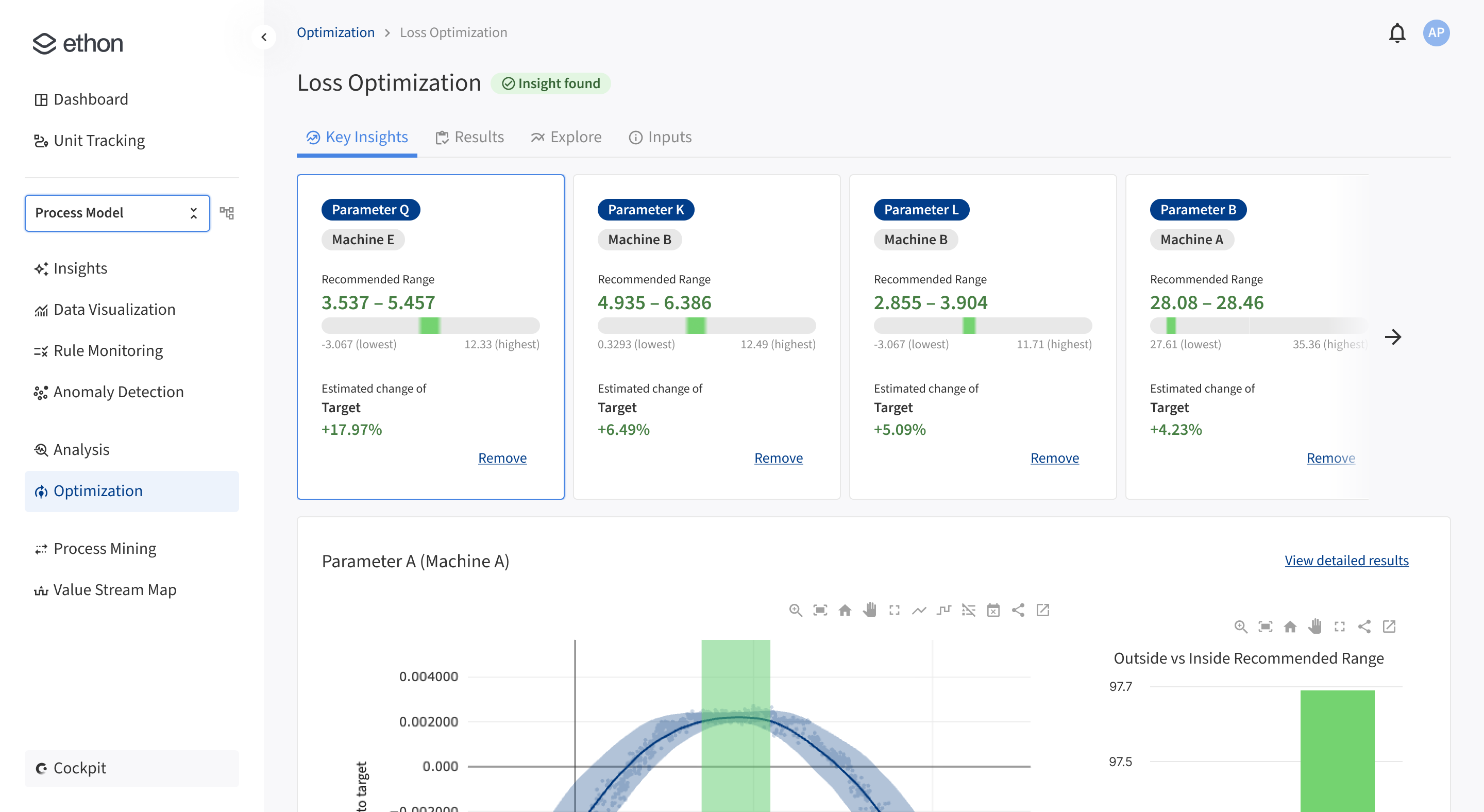

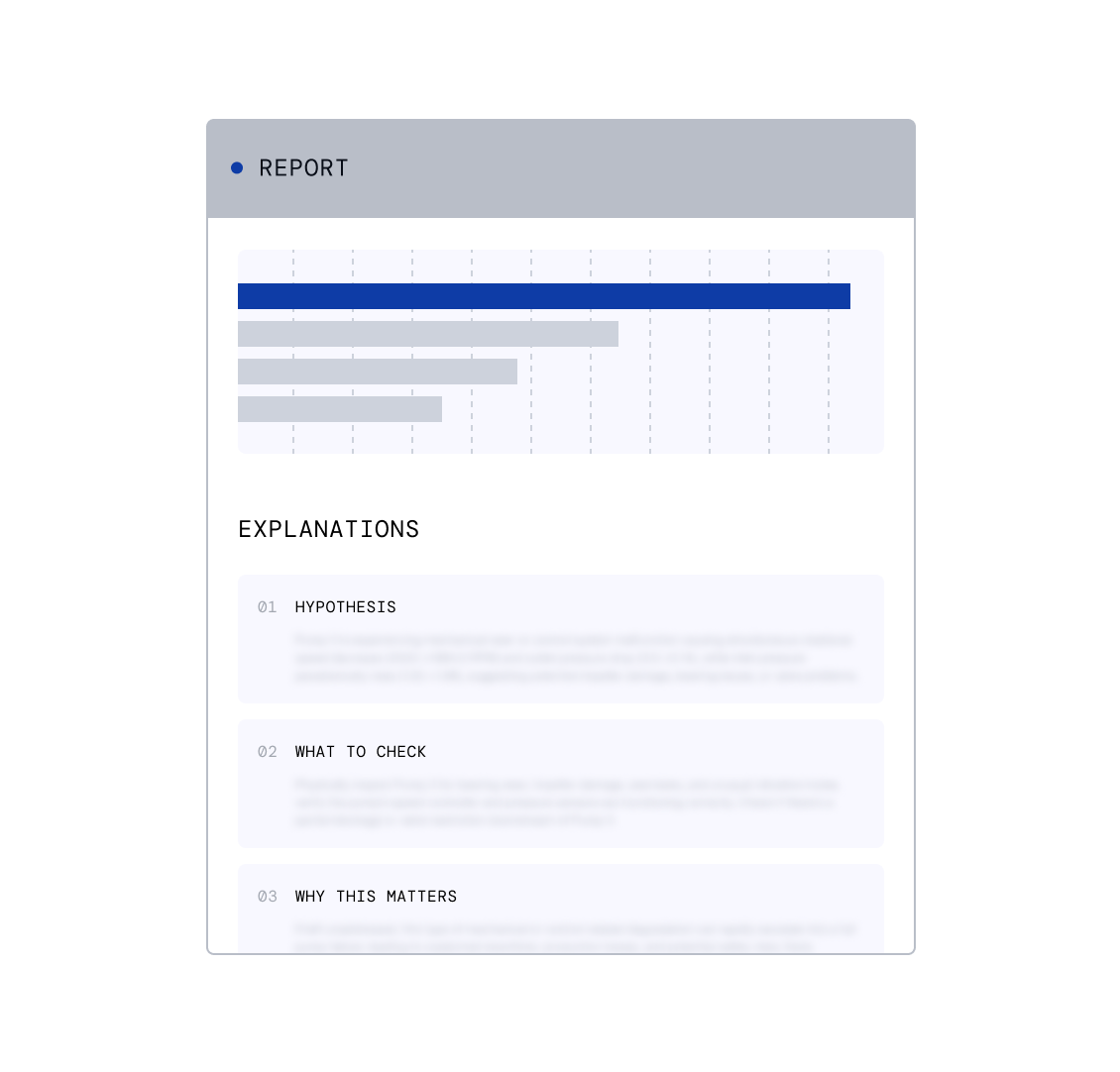

Identify optimization levers

The causal model quantifies which parameters drive performance variation across the process. Users receive a ranked view of influential inputs and process steps, highlighting where improvements matter most.

Recommend optimal setpoints

Based on the causal graph and historical behavior, Ethon computes recommended setpoints for key parameters. Each recommendation includes a quantified impact estimate and direction of change.

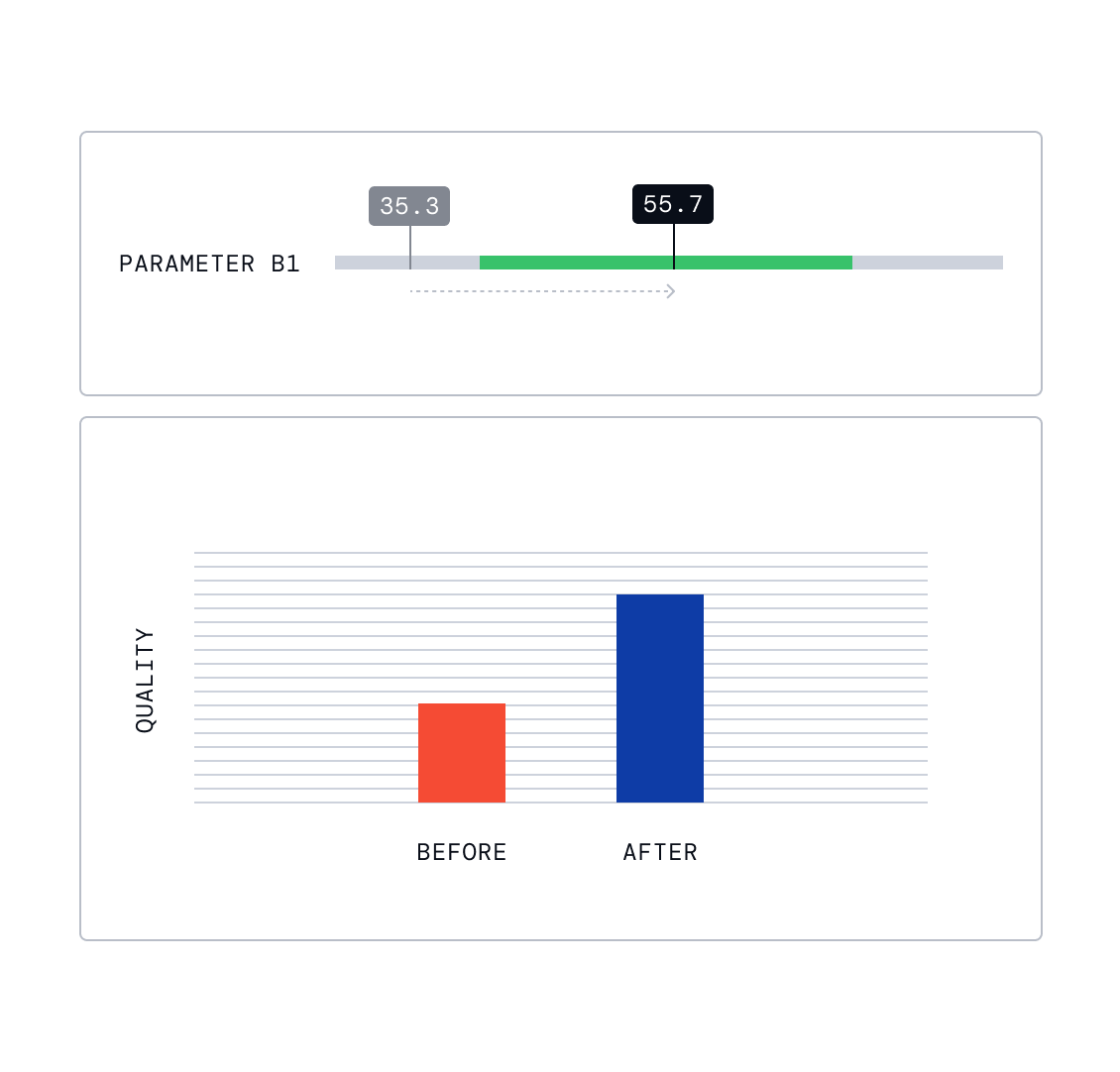

Simulate improvement scenarios

Users can simulate how adjustments to specific parameters would affect process outcomes. The interface compares current performance with simulated scenarios to reveal optimal operating conditions.

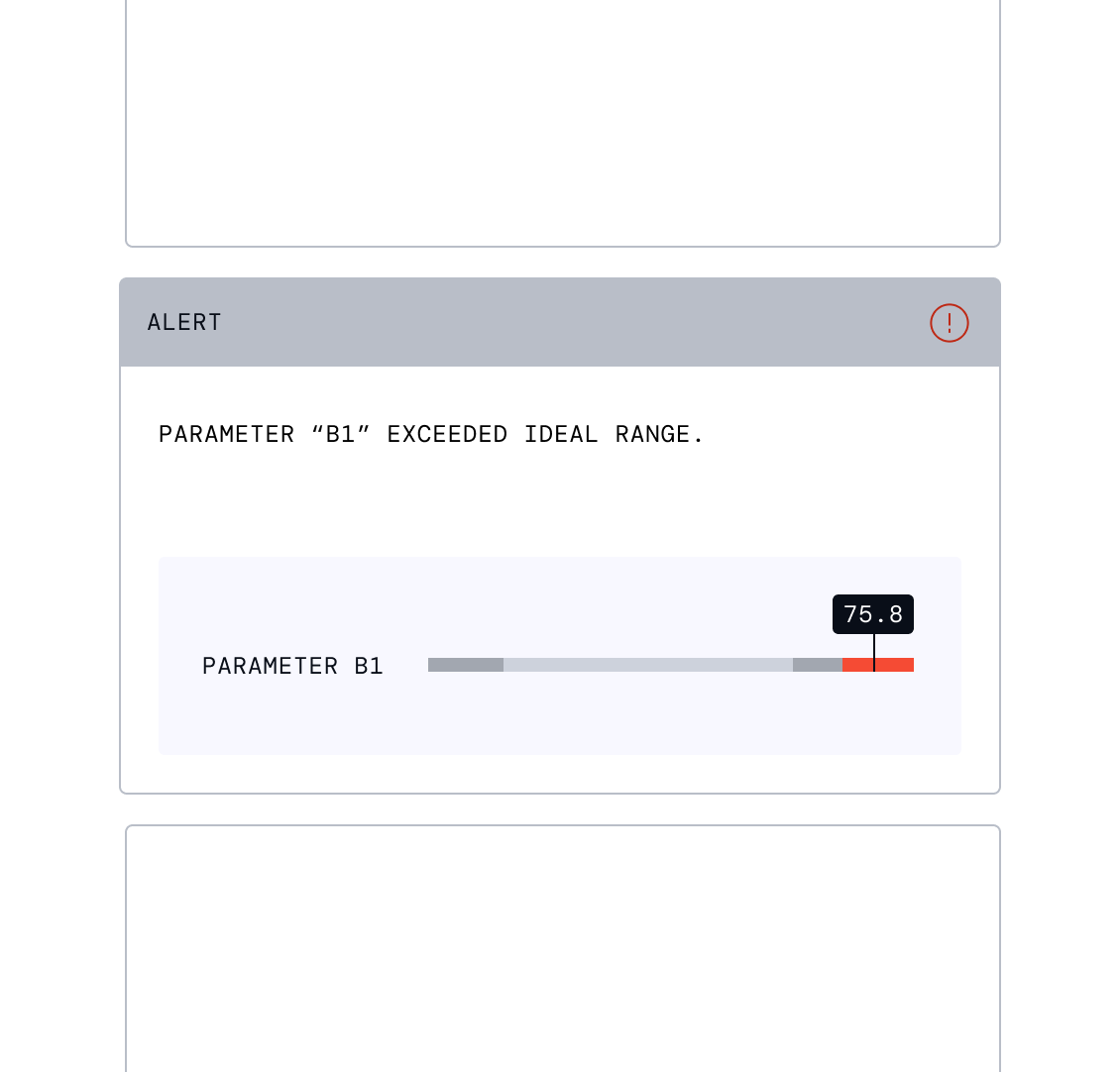

Lock in gains with rule-based monitoring

Users convert recommended ranges into rule-based monitors. These rules track adherence in real-time and alert the shop floor when parameters deviate from optimized ranges, ensuring the process stays within its ideal window.