Predict downtime and quality losses

Stay ahead of process deviations and equipment failures with real-time awareness. Ethon continuously monitors live production data, flags anomalies, and prescribes the right actions to prevent downtime and quality losses before they happen.

Detect, alert, and act on process deviations before losses materialize.

The first fault detection workflow that combines Causal AI with multivariate anomaly detection.

Customers identify mechanical and process degradation far earlier than with traditional threshold- or rule-based monitoring.

Early alerts enable maintenance teams to intervene before minor process deviations escalate into major disruptions such as unplanned line stops, or scrap events.

Achieved through avoided breakdowns, stabilized processes, and fewer emergency maintenance interventions.

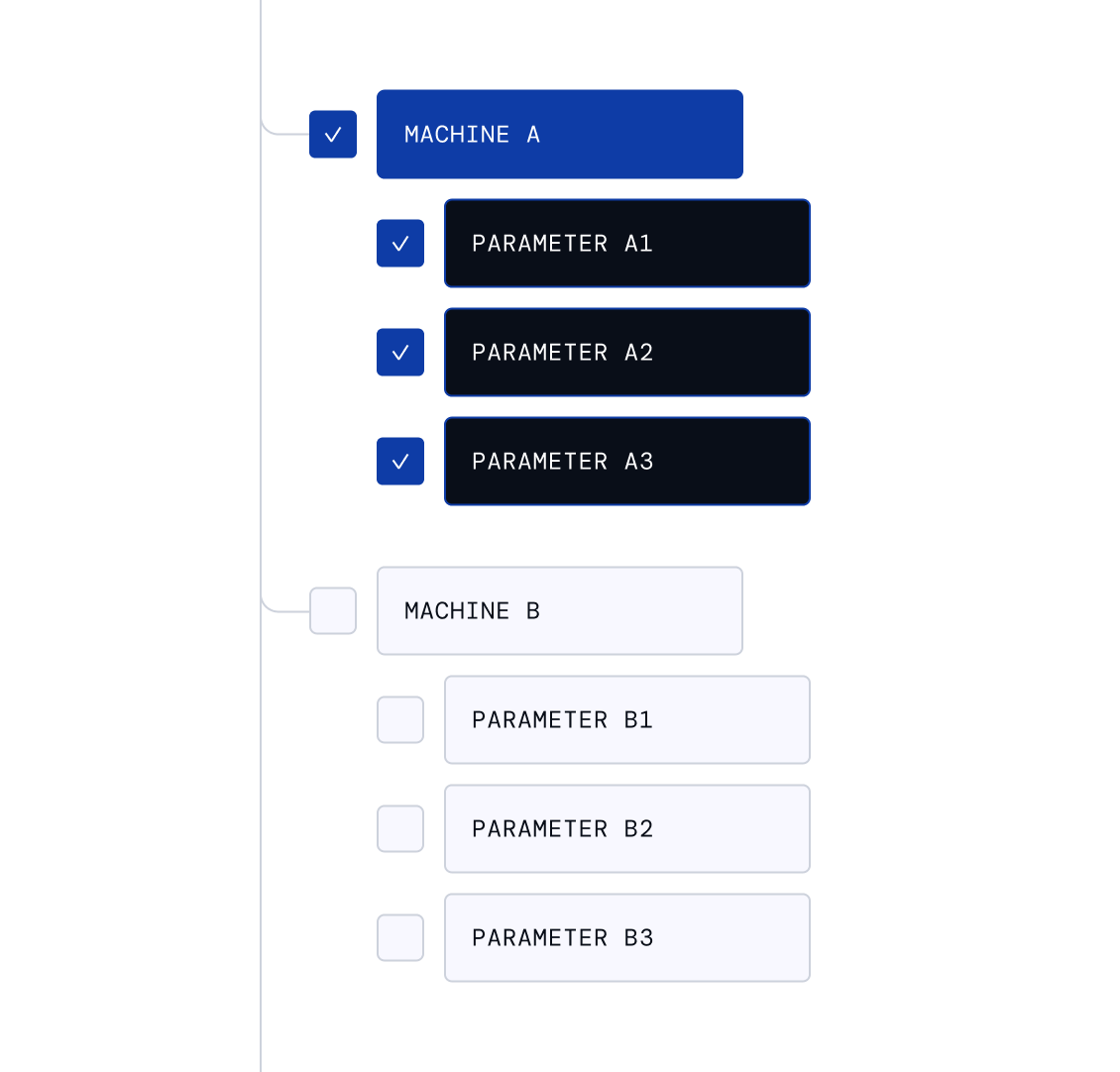

Select what to monitor

Users choose the parameters they want to monitor — from individual signals to complete equipment groups. Any type of measurement can be included (e.g., temperatures, vibrations, pressures, speeds, flows, or other process variables), allowing precise, asset-specific monitoring setups.

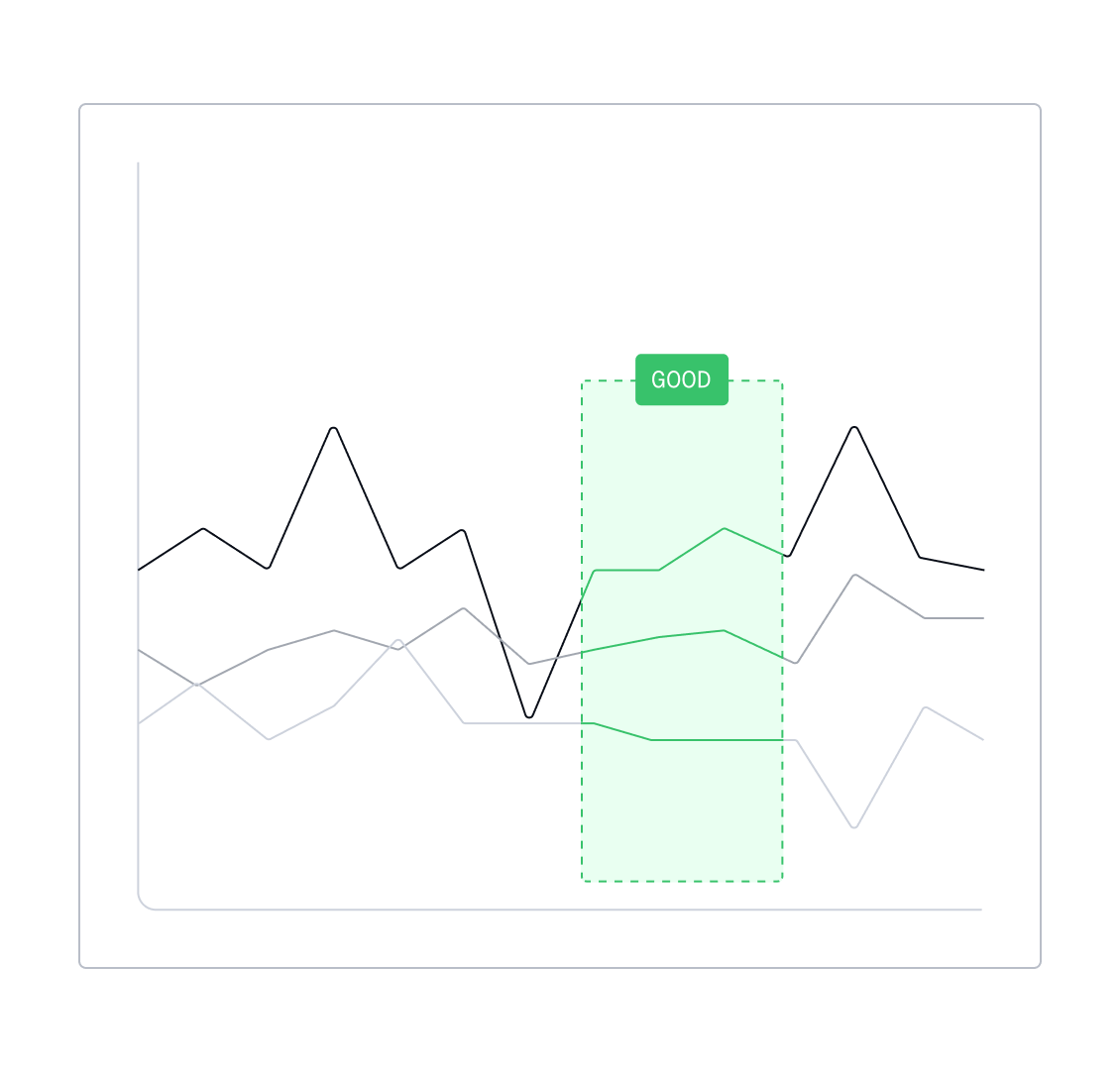

Define normal behavior

Users select time windows or batches where the process or equipment was behaving normally. These instances form the baseline that captures what healthy multivariate behavior looks like.

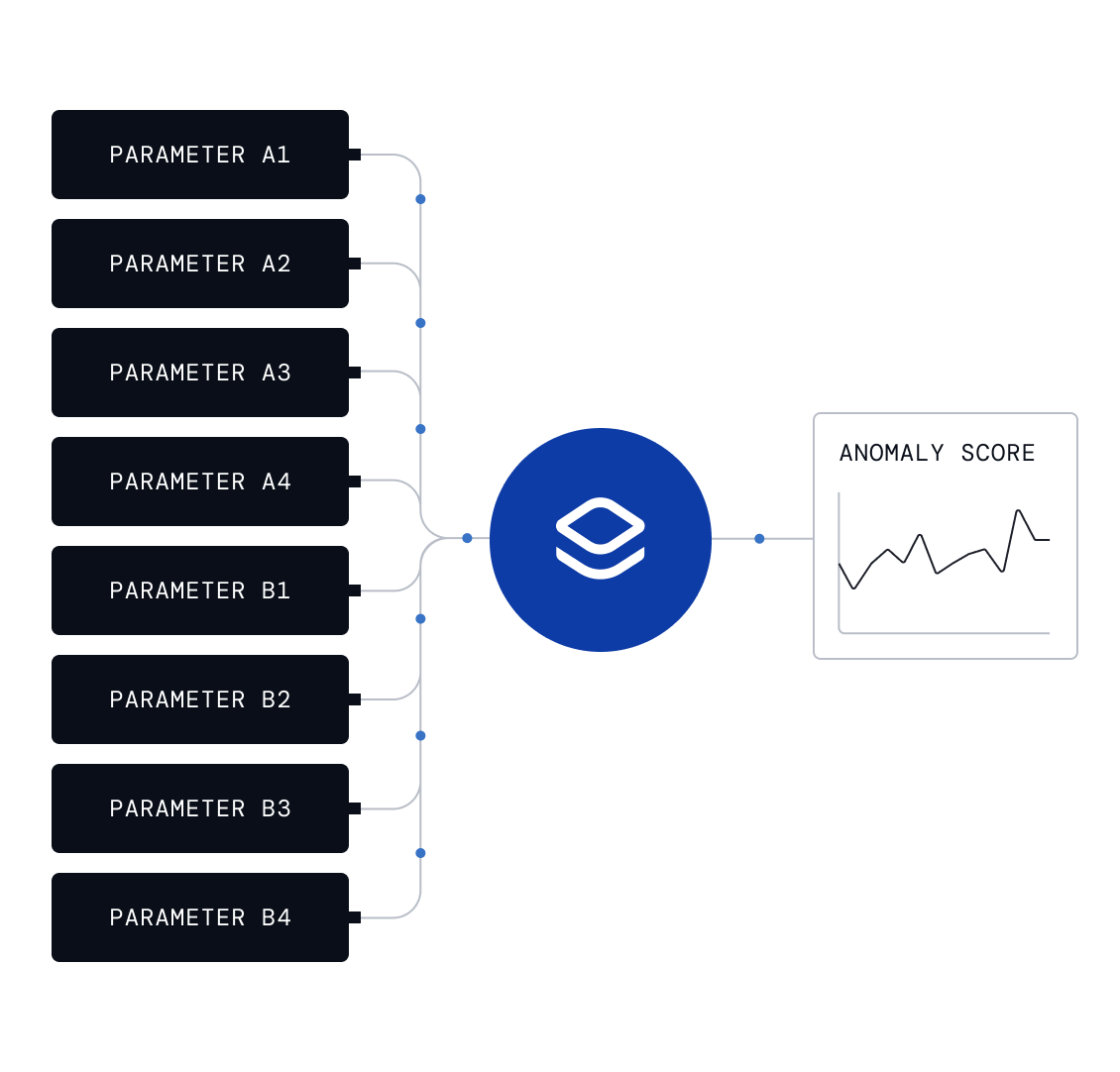

Learn the healthy baseline

Ethon learns the normal interaction patterns across all monitored parameters. The resulting model provides a robust multivariate baseline without requiring manual thresholds or domain knowledge.

Monitor conditions continuously

Autonomous agents continuously compare live data against the learned healthy state. Any deviation from expected multivariate behavior triggers an anomaly, enabling early detection of emerging equipment or process issues.

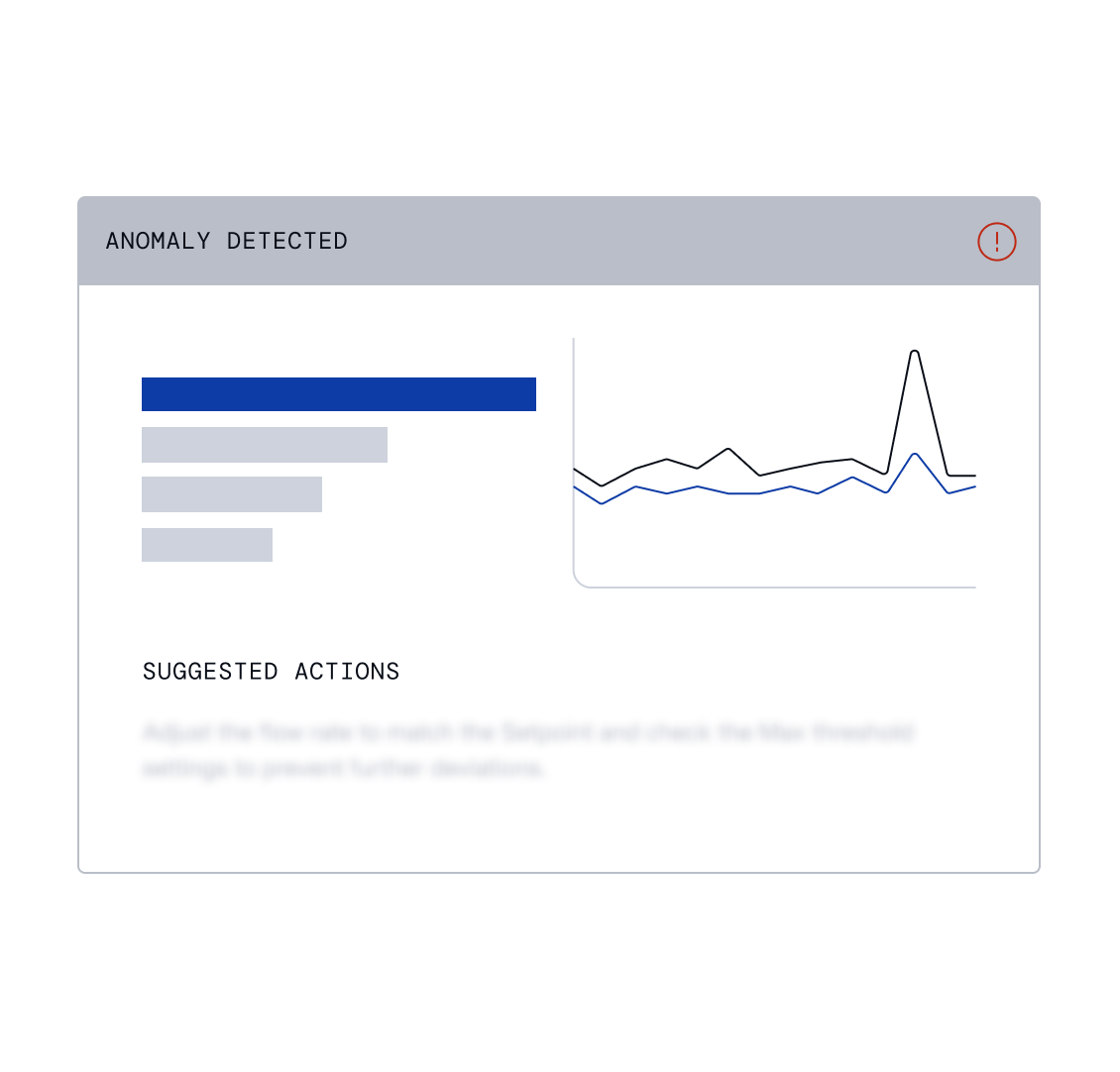

Alert teams instantly

When anomalous behavior is detected, Ethon issues alerts through dashboards or email. Each event includes an anomaly score and a transparent ranking of the parameters contributing most to the anomaly, thereby supporting rapid intervention.