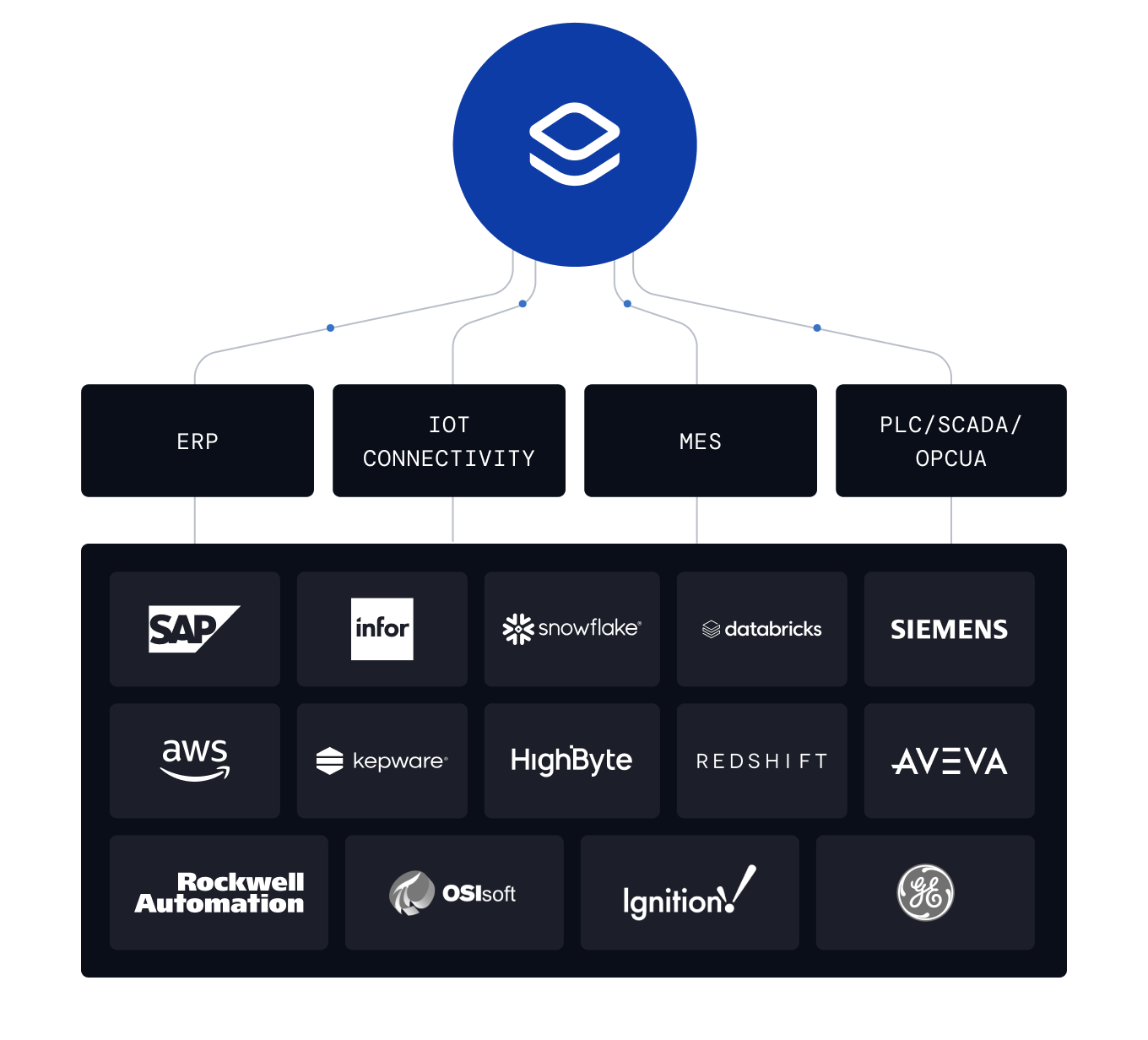

Deployment & Integrations

Ethon runs on top of your existing IT/OT systems, and includes change management to keep your people at the center.

Universal compatibility with all common data sources in factories such as Historians, MES, IoT platforms, and UNS across your IT/OT stack.

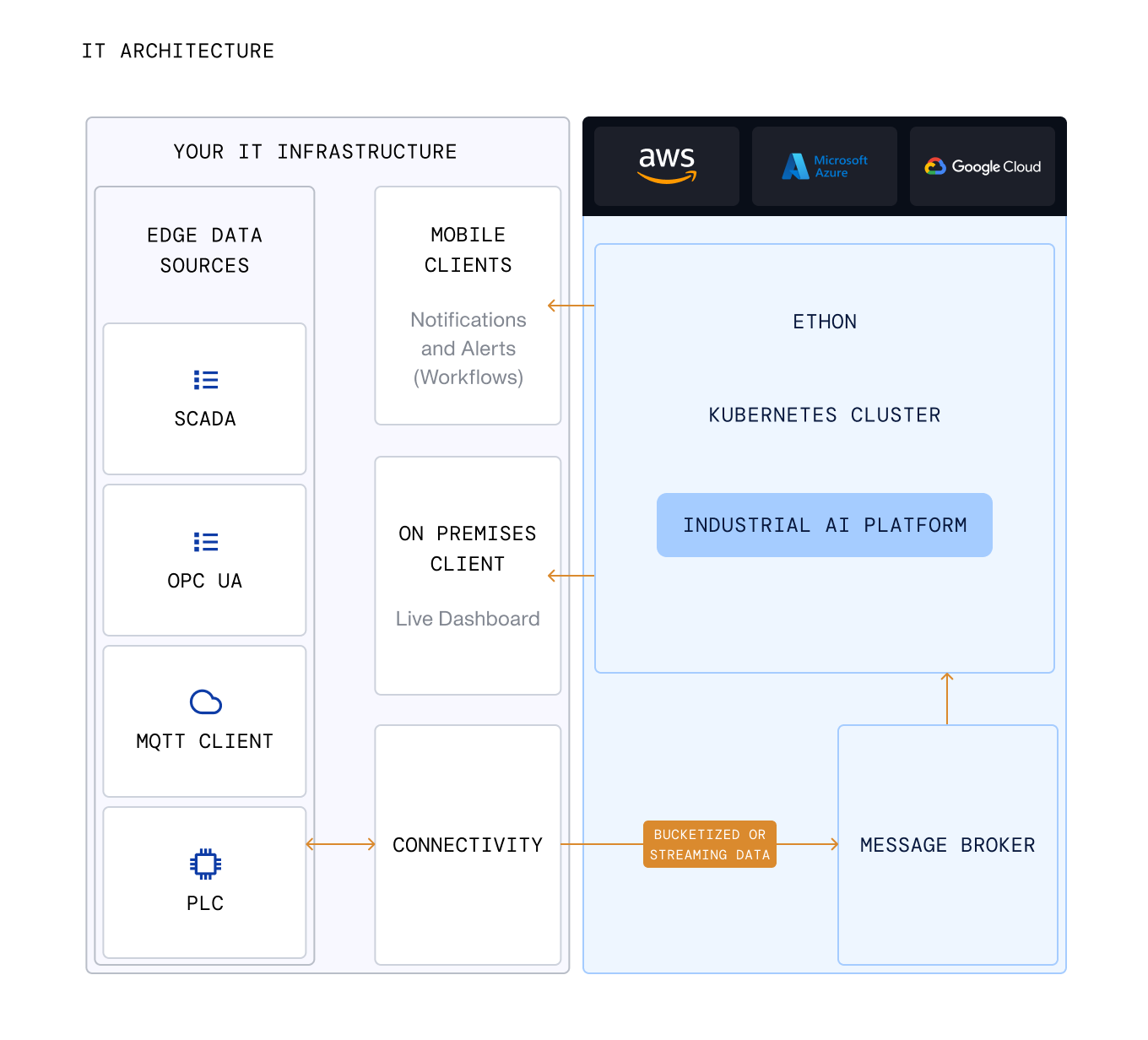

Select the cloud provider, hosting region, and data communication protocol that best align with your organization's needs and policies.

Our forward-deployed team provides change management, and takes care of hosting, updates, and backups — zero maintenance for you.

Built for your reality

Integrates out of the box with existing factory landscapes

Fitting your preferred modern way of communication

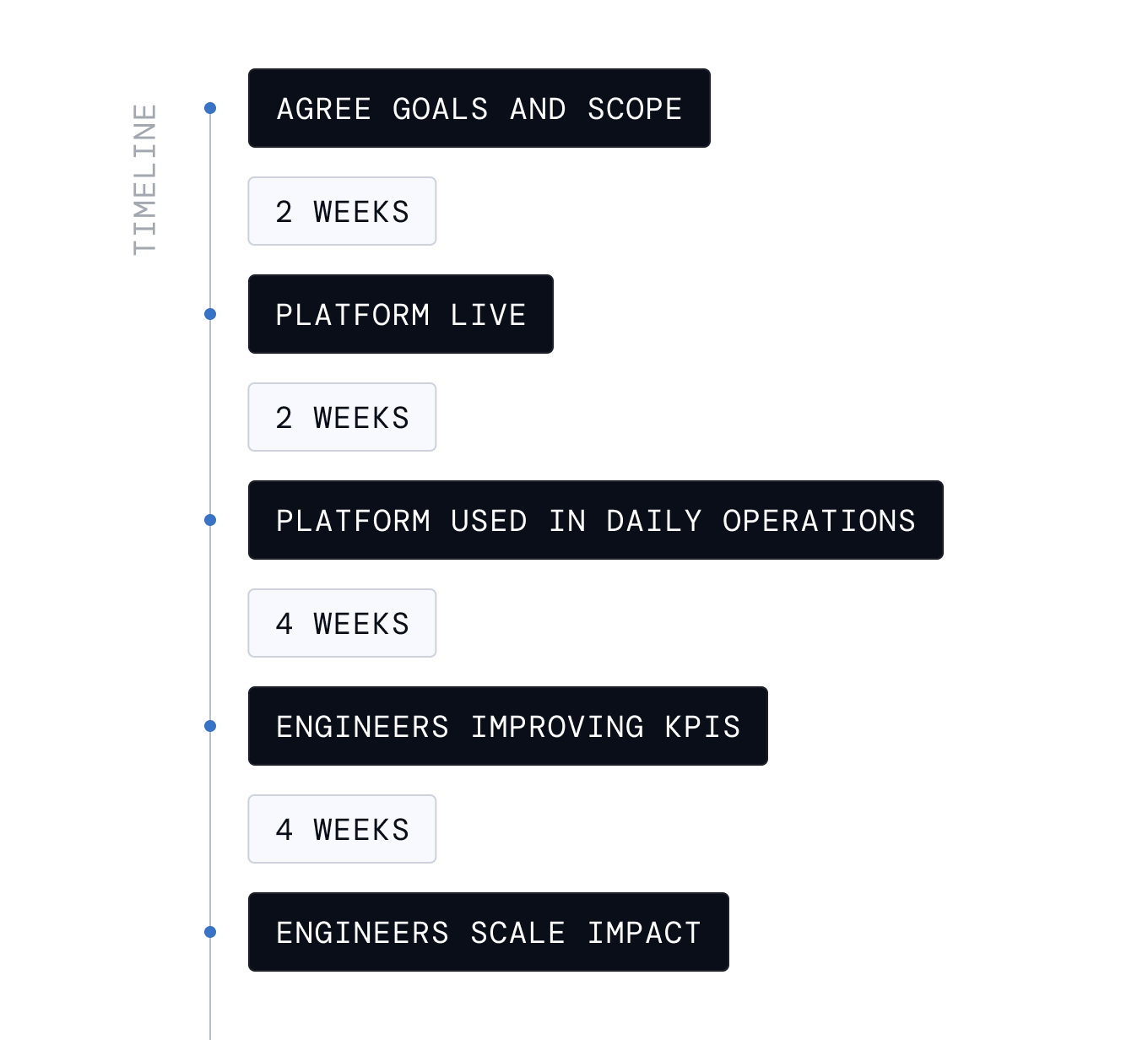

Delivering results E2E making your workforce lives easier

Worried about data readiness? Deploy our AI-Native Historian & MES structure and go-beyond the legacy stack

| Functionality | Historian | MES | Ethon |

|---|---|---|---|

|

Machine data collection (states, tags, alarms)

|

|

|

|

|

Time series data storage

|

|

|

|

|

Data aggregation / KPI calculation

|

|

|

|

|

Production order execution

|

|

|

|

|

Interlocking

|

|

|

|

|

Routing & Operations tracking

|

|

|

|

|

Process Monitoring dashboards

|

|

|

|

|

Anomaly Detection

|

|

|

|

|

Root Cause Analysis

|

|

|

|

|

Agentic Workflows

|

|

|

|

|

Deploy Custom Models

|

|

|

|

|

Cross-Line/Cross-Site Learning

|

|

|

|

|

Advanced Process Control

|

|

|

|

Proof over promise. See what we’ve delivered.

Establishing a global standard for optimizing and controlling chocolate production lines. Saved millions of chocolate truffles through data-driven setpoint recommendations.

Powering visual inspection workflows across 20 factories. Delivered $10M+ in savings by replacing legacy quality systems and supporting a zero customer-complaint target.

Stabilizing processed food production with data-driven centerlining and setpoint recommendations. Delivered ~$100k in cost savings per line per year by reducing material usage.

Enabling cross-factory root cause analysis. Awarded with the 2024 Open Bosch Award for significant reductions in CO₂ emissions, scrap, and rework.

Identified critical quality drivers across 3,000+ transistor manufacturing process parameters, resulting in a 51% scrap reduction. Delivered $1M+ in increased sales.

Supporting complex assembly operations amid labor shortages. Enabling (junior) engineers to deliver reliable root cause analysis across hundreds of process parameters.

Increasing first-time-right in chemical production through data-driven centerlining. Reduced manual batch rework by 72%, lowering unit costs and improving productivity.