Move fast when things break

Uncover the root causes of production issues in minutes, not days. When something goes wrong, Ethon instantly runs a root cause analysis across all process data and surfaces the parameters driving the issue.

Detect, explain, and resolve production issues faster and more precisely than anytime before.

The first root cause analysis that provides automated diagnostics with Causal AI technology.

Benchmarks show Ethon’s causal models consistently uncover more relevant drivers than other causal discovery methods.

Customers have solved complex production issues in minutes instead of weeks through automated diagnostics.

Verified causal insights and faster resolution eliminate recurring issues while reducing downtime, scrap, and product recalls.

Detect emerging issues automatically

Ethon continuously scans thousands of process parameters to flag anomalies and emerging issues in real time. Each detection automatically creates an incident and launches a diagnostic workflow.

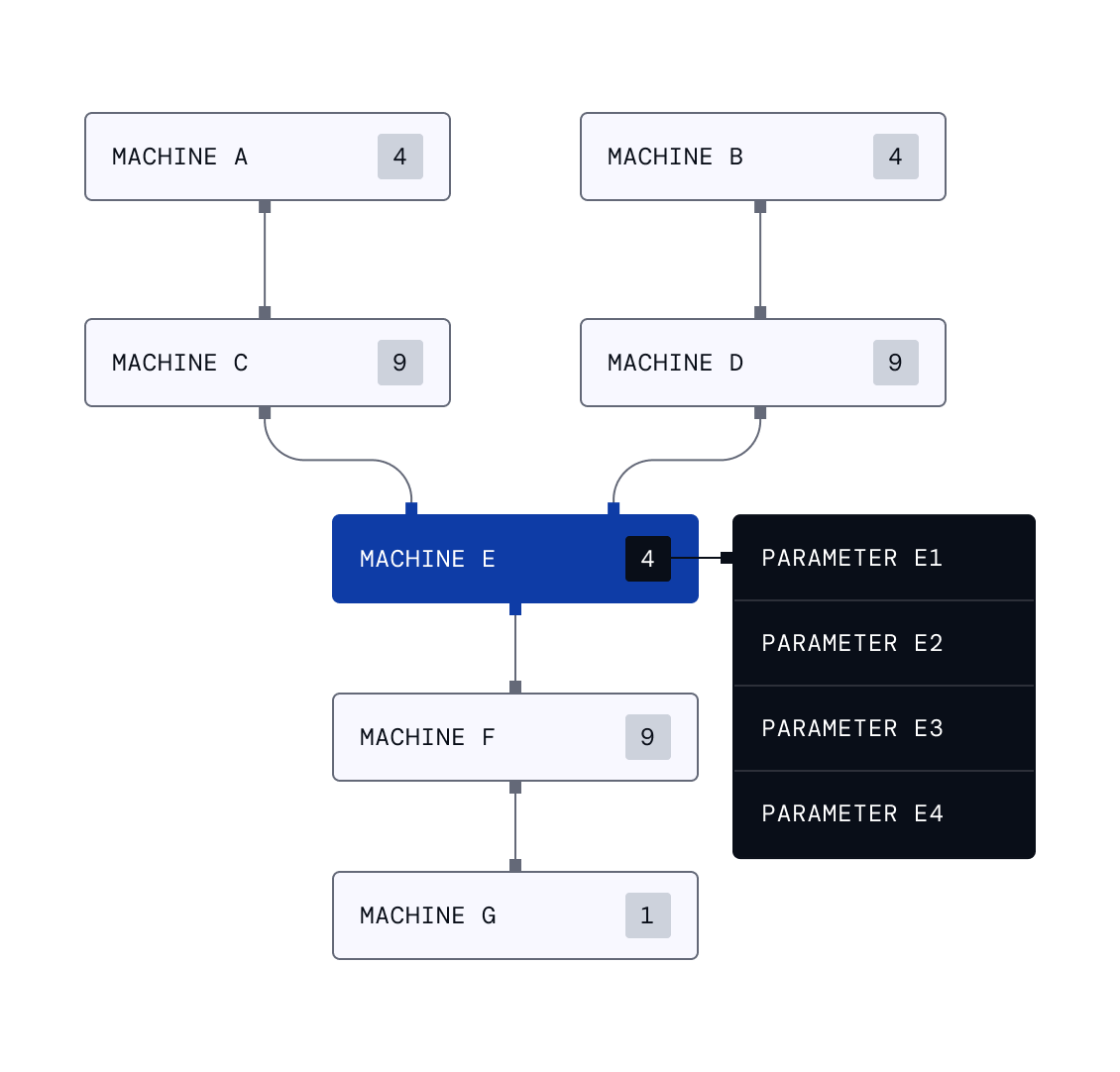

Auto-aggregate all relevant data

Once an issue is detected, Ethon brings together all relevant parameters and context. The workflow uses the process knowledge graph to mirror how production actually works, ensuring every analysis starts with a complete and correctly framed dataset.

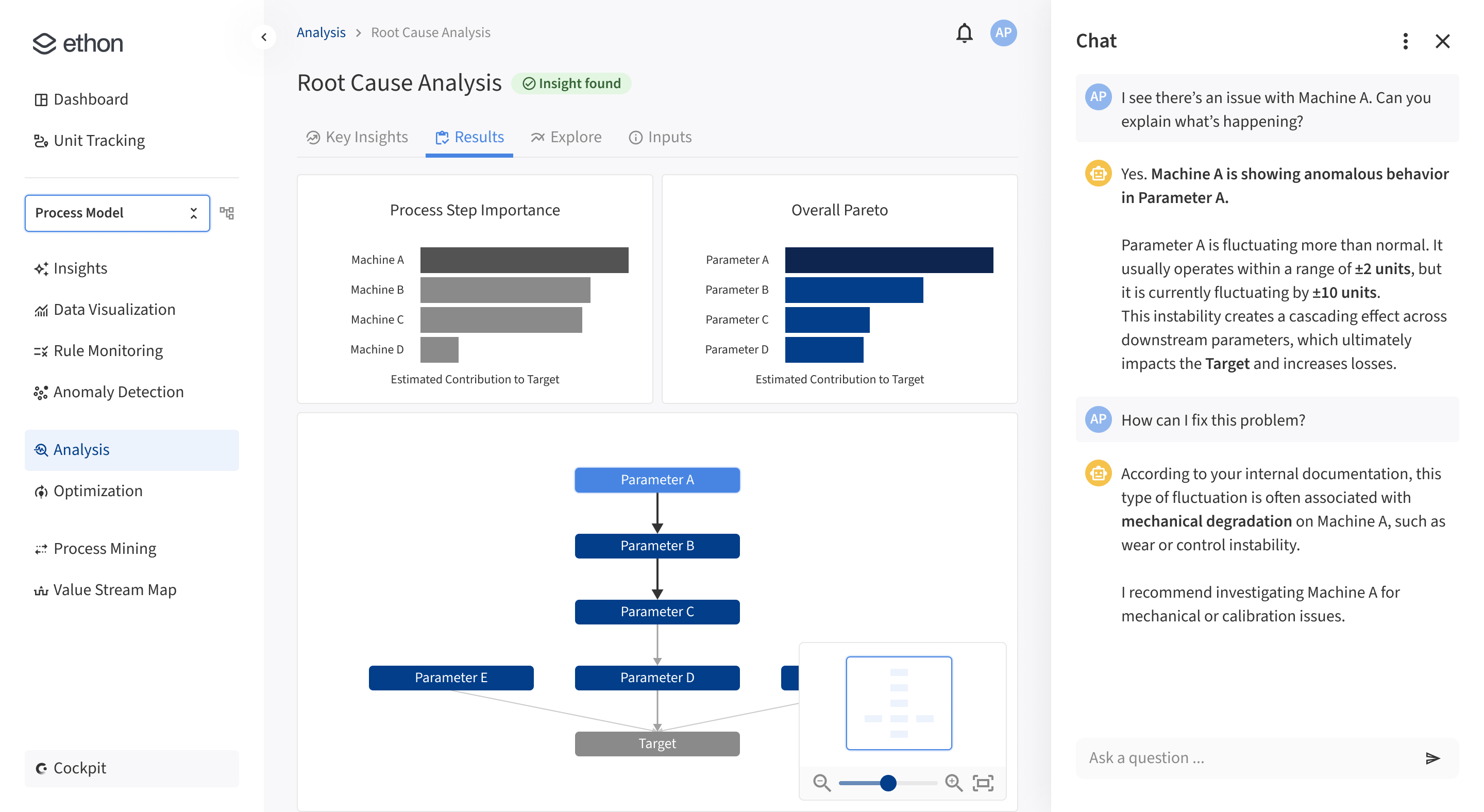

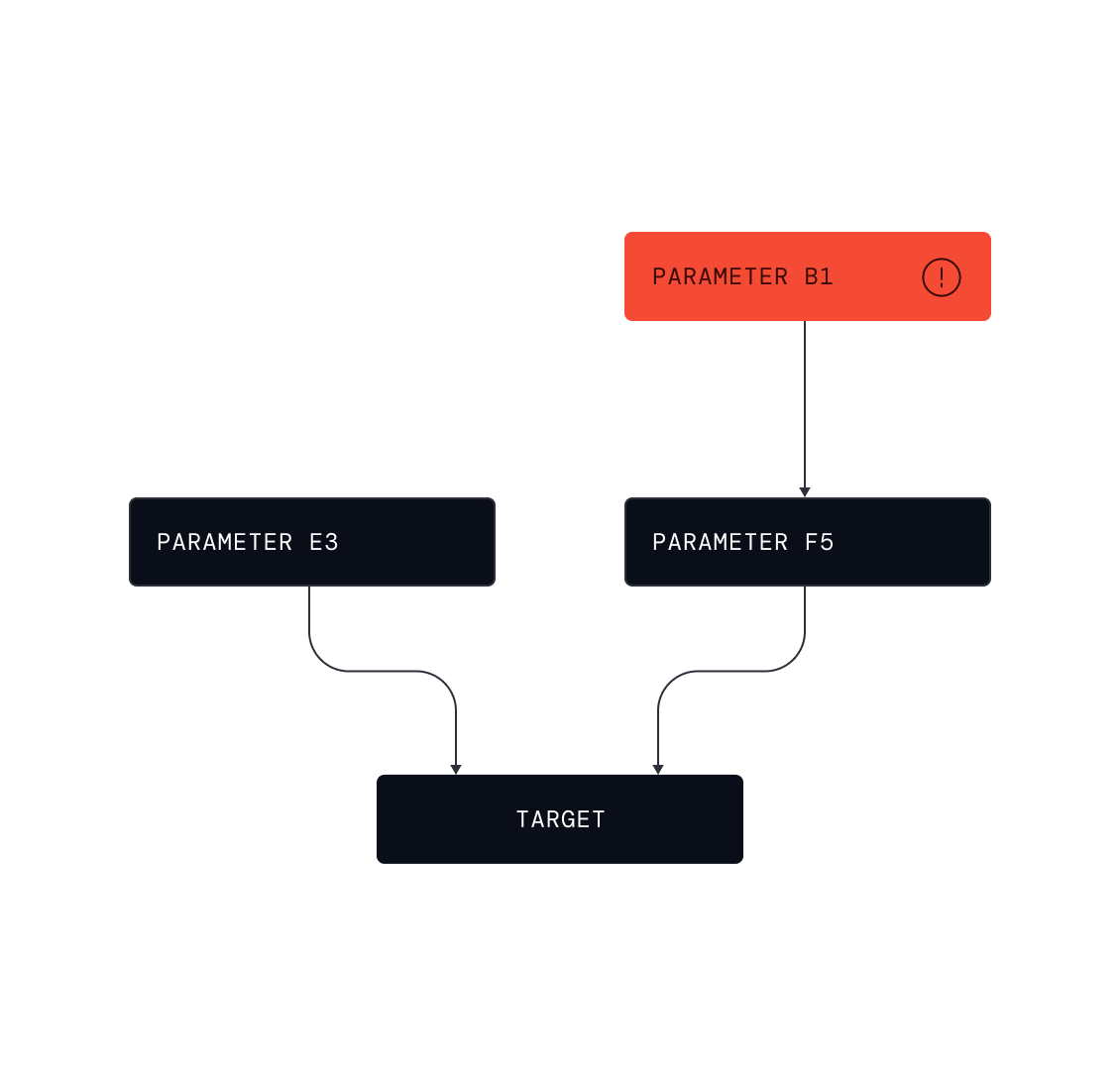

Model root causes automatically

Ethon's Reasoning Model builds a causal graph that mirrors the physical relationships within the process. It models how parameters influence one another, reveals the interaction patterns behind the deviation, and produces a graph-based view of the drivers most likely responsible for the issue.

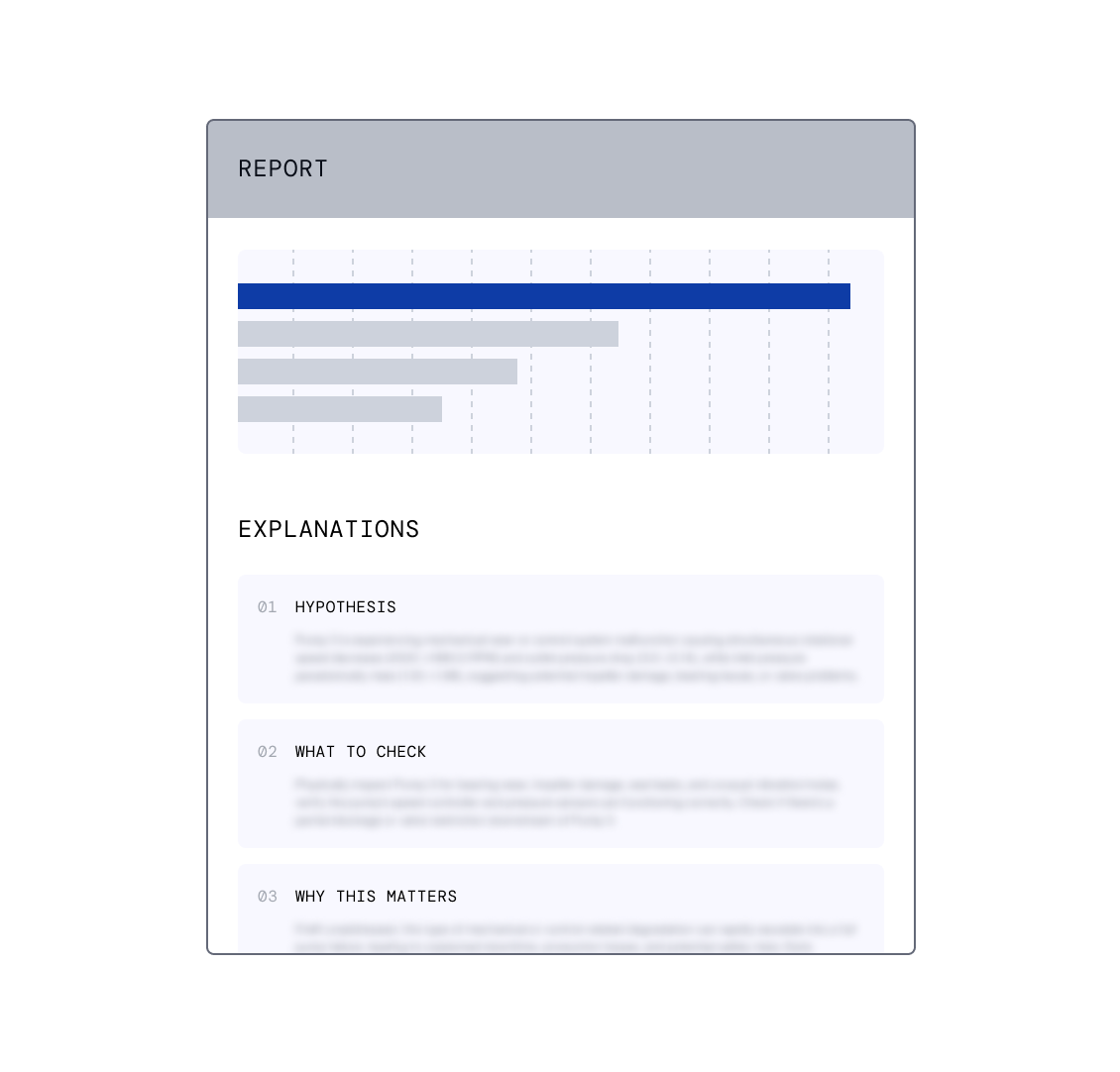

Explain root causes in plain language

Ethon translates the causal graph into a clear, structured report. It summarizes what happened, explains why the issue occurred, and highlights the key drivers in plain language — supported by ranked parameters, visual graphs, and quantified effects.

Turn findings into repeatable SOPs

Engineers can turn findings into SOPs, rule-based monitors, and prescribed corrective actions. Ethon alerts operators when defined conditions recur, ensuring issues are addressed consistently, preventing repeated failures, and embedding process knowledge into daily operations.