Understand, improve, and control

production processes at scale

Ethon unifies production data, enriches it with context, and uses agentic workflows with causal reasoning to help engineers and operators drive productivity at scale.

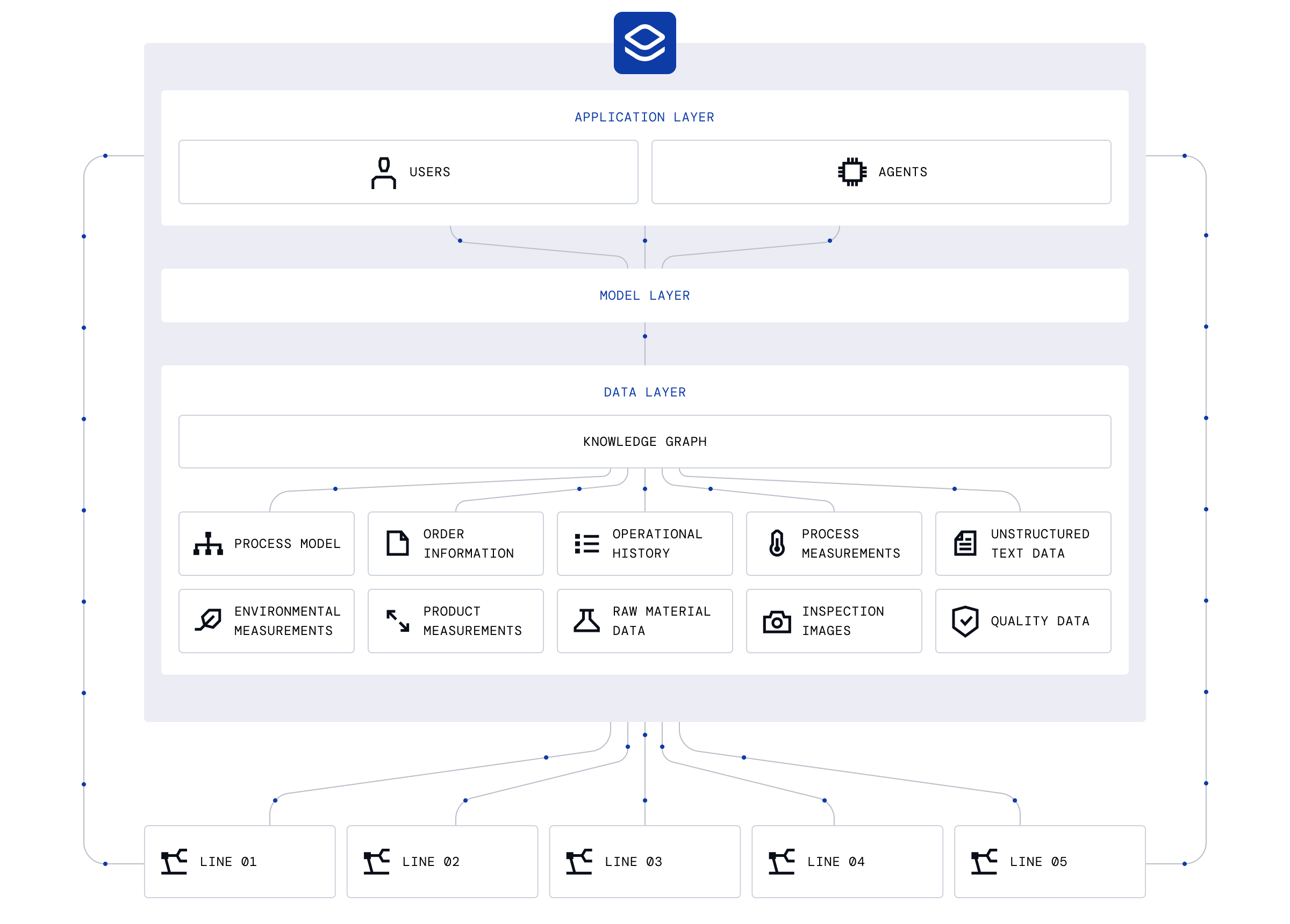

Connect and contextualize all production data

Connects with existing infrastructure such as Historians, MES, IoT platforms, and UNS

Unifies and structures live as well as historical data across IT & OT systems

Adds semantic context to production data without replatforming or new hardware

Connects data sources with real-time and batch ingestion. Deployable as an AI-native Historian & MES-light or as an overlay on existing systems with UNS.

Adds semantic context by mapping data tags to process steps, equipment, batches, and products — reflecting real process dependencies.

Builds a process knowledge graph that mirrors how production runs and serves as the foundation for all agentic workflows.

Designed to scale across factories, with secure cloud streaming and proven in multi-site customer deployments with 20+ factories.

Fine-grained access control, encryption, audit trails, and full data lineage, compliant with ISO 27001 and enterprise security standards.

API-first, with data accessible or exportable via MQTT, REST, and Python SDKs for use in notebooks and custom applications.

The first foundation model built for complex manufacturing processes

Models cause–effect relationships across production processes without manual customization

Understands what happens and why, unlocking gains in cost, quality, and speed

Powers agents that operate within defined process logic and cannot hallucinate actions

A foundation model trained on billions of production scenarios to reason about physical cause–effect relationships in manufacturing processes.

Provides a structured understanding of production by modeling lines, steps, equipment, products, and time as they actually operate in the factory.

Identifies the process parameters that causally influence production outcomes, separating cause from correlation.

Captures process knowledge such as constraints, dependencies, and documented expertise directly in the model, preserving know-how as teams change.

Interprets time-series, batch, unit, and visual data within a single process-aware model, keeping all data linked to its production context.

Provides the execution layer for agents that operate within defined process logic, ensuring actions are constrained to valid, non-hallucinated outcomes.

Unlock millions in value with agentic workflows

System of action that scales capabilities of process engineers and operators with agentic workflows

Accelerates complex analysis and decision-making for engineers and operators by up to 100x

Enables enterprise learning and scales proven improvements consistently across lines and factories

Automatically identifies and explains the causes of production issues from thousands of process variables.

Continuously analyzes process data to uncover hidden waste and recommend optimal parameter setpoints.

Detects drifts and automatically recommends or adjusts setpoints based on current operating conditions.

Reliably measures product quality by integrating with vision systems to detect and count defects.

Flags anomalies in real time and prescribes corrective actions to prevent downtime and production losses.

Tracks every part and batch across process steps to provide full transparency of material flow.

Benefits

Breaks down data silos by connecting and contextualizing production data across systems. Serves as your AI-native Historian & MES-light, or intelligence layer above existing infrastructure.

Proprietary reasoning model based on Causal AI reveals how processes actually behave, enabling decisions based on cause-effect relationships, not surface-level correlations.

Links insights directly to actions, enabling agentic workflows that keep processes optimized, stable, and continuously improving in real-time.

Deploys fast and scales effortlessly across sites, delivering measurable results within a few weeks.

Operates reliably across multi-site, multi-region deployments. Proven with Fortune 500 manufacturers generating $20M+ in value.

Enterprise-grade, modular, and secure by design. Built to ensure robustness, data integrity, and uptime in demanding production environments.

Frequently asked questions

Integration is delivered side-by-side with your teams by a forward-deployed team of manufacturing, IT/OT, and AI experts. We handle connectivity, data modeling, and change management so Ethon works with your processes from day one — not as a disconnected IT project.

Ethon is cloud-agnostic and runs on AWS, GCP, or Azure, supporting secure batch and real-time data ingestion.

Ethon's platform goes much further than these point solutions. It built on the first foundation model for manufacturing, trained on billions of production scenarios to learn how processes behave. This allows Ethon to model cause–effect relationships across parameters, materials, equipment, and conditions — not just correlations.

Using agentic workflows with causal reasoning, Ethon explains why outcomes change and what to do next, helping teams stabilize processes, reduce losses, and scale improvements across production.

Applications run out of the box and are driven by the platform’s reasoning capabilities and agentic workflows. Analyses are triggered automatically, results are explained in plain language, and recommended actions are directly tied to process behavior — no model building, scripting, or manual data preparation required.

Data scientists love Ethon too. They can use a Jupyter-based scripting environment to access curated production data and extend workflows.

Customers typically generate measurable value within three months.

The platform is built on a scalable, cloud-based architecture and is proven in enterprise deployments, including customers running Ethon across 20+ factories within a single organization. This allows manufacturers to standardize analytics and workflows centrally, while respecting local differences at each site.